| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8708305090 | Doc | 2.5% <u></u>+55.0% | CN | US | 2025-05-12 |

| 8708305030 | Doc | 2.5% <u></u>+55.0% | CN | US | 2025-05-12 |

| 8714998000 | Doc | 47.5% | CN | US | 2025-05-12 |

| 8708305020 | Doc | 2.5% <u></u>+55.0% | CN | US | 2025-05-12 |

| 8708305090 | Doc | 2.5% <u></u>+55.0% | CN | US | 2025-05-12 |

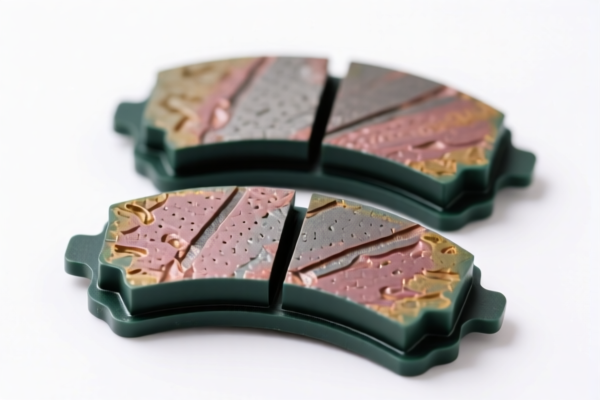

Resin Brake Pads

Resin brake pads are a type of brake pad used primarily in braking systems to create friction and slow or stop a vehicle or mechanism. They are distinguished by their primary constituent material: resin.

Material Composition

These pads are formulated using a blend of organic compounds—primarily phenolic resins—combined with reinforcing materials like organic fibers, graphite, Kevlar, and other friction modifiers. The specific composition varies significantly between manufacturers and intended applications. Unlike metallic or ceramic brake pads, resin pads contain minimal metal.

Purpose and Function

The primary purpose of resin brake pads is to provide sufficient friction when pressed against a brake rotor (or disc) to convert kinetic energy into thermal energy through friction. This conversion slows or stops the rotation of the rotor, thus slowing or stopping the associated mechanism. The resin matrix binds the friction material together and provides structural integrity.

Usage Scenarios

Resin brake pads are commonly used in:

- Bicycles: Especially mountain bikes and road bikes, where modulation and quiet operation are prioritized.

- Motorcycles: Often found in lower-performance motorcycles and scooters.

- Light Vehicles: Some light vehicles utilize resin pads where noise and dust generation are concerns.

- Industrial Applications: Light-duty industrial machinery and equipment.

Common Types & Characteristics

- Organic Brake Pads: This is often used interchangeably with resin brake pads. They offer excellent initial bite and quiet operation.

- Semi-Metallic Resin Pads: These incorporate a small percentage of metal for enhanced stopping power and durability. They offer a balance between organic and metallic pad characteristics.

- Kevlar Resin Pads: These pads use Kevlar fibers for increased strength and heat resistance. They are often used in high-performance applications.

Advantages

- Quiet Operation: Resin pads generally produce less noise than metallic pads.

- Good Modulation: Provide predictable braking power and control.

- Rotor-Friendly: Less abrasive than metallic pads, reducing wear on rotors.

- Cost-Effective: Typically less expensive than ceramic or metallic pads.

Disadvantages

- Lower Stopping Power: Generally provide less stopping power compared to metallic or ceramic pads.

- Lower Heat Resistance: Can fade more quickly under prolonged or heavy braking.

- Shorter Lifespan: Tend to wear down faster than metallic or ceramic pads.

- Sensitivity to Moisture: Performance can be reduced in wet conditions.

According to the provided reference material, the HS code options related to 'RESINBRAKEPADS' are limited, with only the following 1 found.

- 8109.20.00

- Chapter 81: Miscellaneous manufactured articles of base metal.

- Heading 8109: Articles of base metal not elsewhere specified.

- Subheading 8109.20.00: Brake blocks, segments, and shoe linings, whether or not covered with friction material. This includes brake blocks and segments for vehicles, and shoe linings, whether or not covered with friction material.

Regarding HS code 8109.20.00, please note the need to verify the material composition of the brake pads.

Customer Reviews

No reviews yet.