| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8203300000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8205595560 | Doc | 60.3% | CN | US | 2025-05-12 |

| 8205595560 | Doc | 60.3% | CN | US | 2025-05-12 |

| 8206000000 | Doc | The rate of duty applicable to that article in the set subject t+30.0% | CN | US | 2025-05-12 |

| 6805301000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6805305000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6815110000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6815910011 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6901000000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6914108000 | Doc | 64.0% | CN | US | 2025-05-12 |

| 6914908000 | Doc | 60.6% | CN | US | 2025-05-12 |

| 3926904000 | Doc | 32.8% | CN | US | 2025-05-12 |

| 3901905501 | Doc | 61.5% | CN | US | 2025-05-12 |

| 3901909000 | Doc | 61.5% | CN | US | 2025-05-12 |

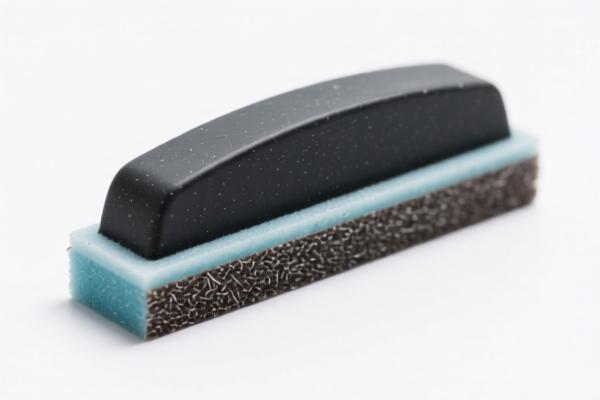

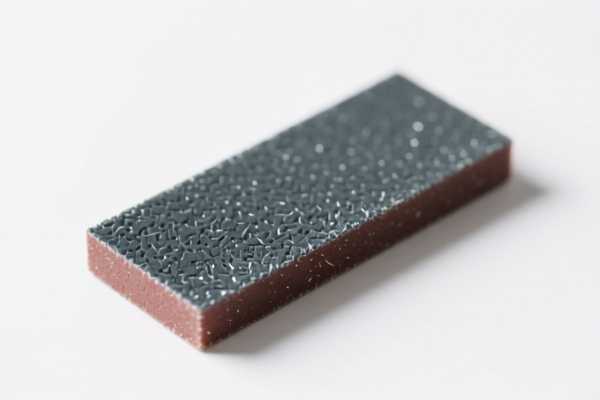

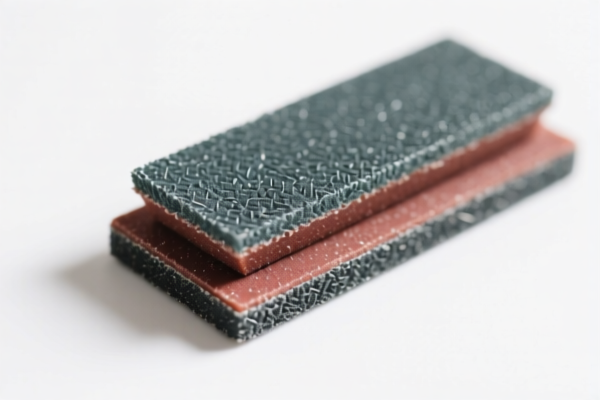

Abrasive Rings

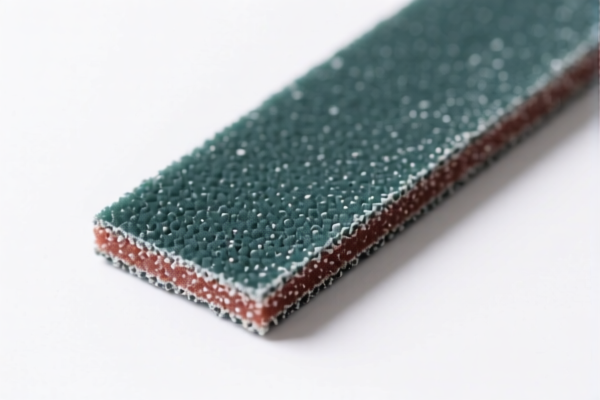

Abrasive rings are specialized tools used in various industrial applications for deburring, edge blending, radius creation, and surface finishing of hard materials, particularly carbides, ceramics, and hardened steels. They are characterized by their abrasive structure bonded to a ring-shaped form, enabling internal and external grinding and finishing operations.

Material

Abrasive rings are constructed using a variety of abrasive grains bonded with a suitable matrix. Common materials include:

- Abrasive Grains:

- Aluminum Oxide (Al₂O₃): Most common, offering a balance of cost, durability, and cutting ability. Available in various purities and grain sizes.

- Silicon Carbide (SiC): Harder and more aggressive than aluminum oxide, suitable for harder materials and faster cutting rates.

- Boron Carbide (B₄C): Extremely hard, used for very hard materials and precise finishing.

- Diamond: Used for the hardest materials and highest precision applications. Both natural and synthetic diamonds are employed.

- Bonding Matrix:

- Vitrified Bond: Provides high rigidity and is suitable for high-speed applications.

- Resin Bond: Offers flexibility and is used for applications requiring quieter operation and better surface finish.

- Metal Bond: Provides the highest strength and is used for heavy-duty applications and aggressive cutting.

Purpose

The primary purpose of abrasive rings is to precisely remove material from a workpiece to achieve desired dimensions, surface characteristics, and edge profiles. Specific applications include:

- Deburring: Removing sharp edges and burrs from machined parts.

- Edge Blending: Creating a smooth transition between surfaces.

- Radius Creation: Forming precise radii on edges and corners.

- Surface Finishing: Achieving specific surface roughness and dimensional tolerances.

- Internal Grinding: Finishing internal diameters and profiles.

Function

Abrasive rings function by utilizing the cutting action of abrasive grains contained within the ring's structure. As the ring rotates against the workpiece, the abrasive grains remove material through micro-chipping and shearing. The bonding matrix holds the grains in place and provides structural integrity to the ring. Coolant is often used to dissipate heat and flush away debris. The ring's shape and abrasive grain size determine the cutting rate and finish quality.

Usage Scenarios

Abrasive rings are employed in a wide range of industries, including:

- Aerospace: Finishing turbine blades, engine components, and structural parts.

- Automotive: Deburring gears, shafts, and other powertrain components.

- Medical: Finishing surgical instruments and implants.

- Die & Mold Making: Precision finishing of die cavities and mold components.

- Cutting Tool Manufacturing: Sharpening and finishing carbide and ceramic cutting tools.

- Electronics: Finishing semiconductor wafers and electronic components.

Common Types

- Mounted Abrasive Rings: Mounted on a mandrel for use on spindle machines.

- Free-Standing Abrasive Rings: Used with specialized holding fixtures or robotic systems.

- Diamond Abrasive Rings: Employing diamond grains for finishing extremely hard materials.

- Internal Grinding Rings: Specifically designed for finishing internal diameters and profiles.

- Formed Abrasive Rings: Shaped to create specific profiles and radii.

- Segmented Abrasive Rings: Composed of multiple abrasive segments for increased cutting efficiency and versatility.

Abrasive rings fall under the category of abrasive products, typically used for grinding, polishing, or cutting materials. Based on the provided information, the following HS codes are relevant:

-

6805301000: This HS code covers natural or artificial abrasive powder or grain on a base of textile material, paper, or paperboard, whether cut to shape or sewn. Specifically, it applies to articles wholly or partly coated with abrasives in the form of sheets, strips, disks, belts, or sleeves. Abrasive rings fitting this description would fall under this code.

- 68: Articles of stone, plaster, lime, cement, asbestos, mica or similar materials.

- 05: Abrasive powder or grain, on a base of textile material, paper, paperboard or other materials.

- 30: On a base of other materials.

- 10: Articles wholly or partly coated with abrasives, in the form of sheets, strips, disks, belts, sleeves or similar forms.

-

6805305000: This HS code also covers natural or artificial abrasive powder or grain on a base of textile material, paper, or paperboard, but applies to "Other" abrasive articles on a base of other materials. If the abrasive ring does not fit the specific description of 6805301000, it may fall under this code.

- 68: Articles of stone, plaster, lime, cement, asbestos, mica or similar materials.

- 05: Abrasive powder or grain, on a base of textile material, paper, paperboard or other materials.

- 30: On a base of other materials.

- 50: Other.

Please note that determining the correct HS code depends on the specific material composition of the abrasive ring and its base material. If the ring is coated with abrasives and formed into sheets, strips, disks, belts, or sleeves, 6805301000 is likely the appropriate code. If it doesn't fit that description, 6805305000 should be considered.

Customer Reviews

No reviews yet.