| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8459510040 | Doc | 59.2% | CN | US | 2025-05-12 |

| 8459690090 | Doc | 59.2% | CN | US | 2025-05-12 |

| 8458995030 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8458995090 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8483908040 | Doc | 57.8% | CN | US | 2025-05-12 |

| 8483908080 | Doc | 57.8% | CN | US | 2025-05-12 |

| 6909112000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6909120000 | Doc | 59.0% | CN | US | 2025-05-12 |

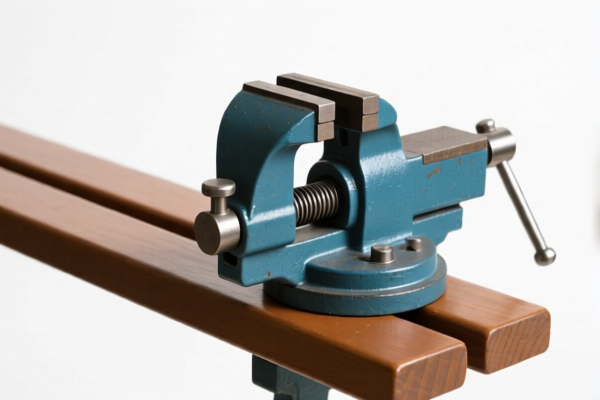

Bench Mill

A bench mill is a small, manually operated milling machine designed for light-duty work. Typically mounted on a workbench (hence the name), it provides a more precise and versatile alternative to hand-filing or drilling for tasks requiring accuracy and repeatability.

Material:

- Frame: Commonly constructed from cast iron for rigidity and vibration damping. Aluminum alloys are used in some lighter-duty models.

- Column: Typically cast iron, supporting the headstock and providing vertical adjustment.

- Table: Usually made of cast iron, often with hardened steel surfaces for wear resistance. May include dovetail slides for X and Y axis movement.

- Spindle: Constructed from hardened steel, providing the rotational force.

- Cutting Tools: High-speed steel (HSS), cobalt HSS, or carbide are common materials for milling cutters.

Purpose:

Bench mills are used for a wide variety of tasks including:

- Metalworking: Creating precise cuts, slots, and pockets in metal.

- Prototyping: Machining small parts for testing and design verification.

- Model Engineering: Fabricating components for scale models.

- Repair Work: Modifying or repairing existing metal parts.

- Jewelry Making: Creating intricate designs in precious metals.

- Educational Purposes: Teaching basic machining principles.

Function:

The core function of a bench mill is to remove material from a workpiece using a rotating cutting tool. The workpiece is securely clamped to the mill's table and moved precisely under the cutter. Key functional components include:

- Spindle: Rotates the cutting tool at various speeds.

- Table: Provides X and Y axis movement, often with a crank mechanism for fine control. Some models also include rotary table functionality for angular cuts.

- Column: Allows vertical (Z-axis) adjustment of the cutting tool.

- Overarm: Supports the spindle and provides rigidity.

- Cutting Fluid System: Many mills incorporate a system for delivering cutting fluid to cool the tool and workpiece, improving tool life and surface finish.

Usage Scenarios:

- Home Workshops: Ideal for hobbyists and DIY enthusiasts.

- Small Machine Shops: Suitable for low-volume production and specialized tasks.

- Educational Institutions: Used in machining courses and labs.

- Jewelry Studios: For creating custom jewelry designs.

- Repair Facilities: Modifying or repairing metal parts.

Common Types:

- Standard Bench Mill: The most common type, offering basic X, Y, and Z axis movement.

- Variable Speed Bench Mill: Allows adjustment of the spindle speed for different materials and cutting tools.

- Power Feed Bench Mill: Includes powered feeds for the X, Y, and Z axes, increasing efficiency and accuracy.

- Digital Readout (DRO) Bench Mill: Equipped with digital scales that display the position of the table, improving precision and ease of use.

- Rotary Table Bench Mill: Features a rotary table that allows for angular cuts and machining of circular parts.

- Mini Mill: A very compact bench mill, suitable for very small parts and delicate work.

Bench mills are machine tools used for drilling, boring, milling, threading, or tapping by removing metal. The following HS codes are relevant based on the provided information:

-

8459510040: This HS code covers machine tools (including way-type unit head machines) for drilling, boring, milling, threading or tapping by removing metal, other than lathes (including turning centers) of heading 8458. Specifically, it refers to milling machines, knee type, that are numerically controlled, used or rebuilt.

- 84: Chapter 84 covers Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof.

- 59: Heading 8459 covers Machine tools for working metal other than those of heading 8457.

- 51: Subheading 845951 covers Milling machines, knee type.

- 0040: Further specifies numerically controlled, used or rebuilt milling machines, knee type.

-

8459690090: This HS code also covers machine tools for drilling, boring, milling, threading or tapping by removing metal, other than lathes (including turning centers) of heading 8458. However, it refers to other milling machines, specifically those categorized as "other" within the "other" category.

- 84: Chapter 84 covers Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof.

- 59: Heading 8459 covers Machine tools for working metal other than those of heading 8457.

- 69: Subheading 845969 covers Other milling machines.

- 0090: Further specifies "other" milling machines within the "other" category.

According to the provided reference material, the HS code options related to 'bench mill' are limited, with only the following 2 found. It is important to determine if the bench mill is numerically controlled or falls into the "other" category to select the correct HS code.

Customer Reviews

No reviews yet.