| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8311900000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8301600000 | Doc | 40.3% | CN | US | 2025-05-12 |

| 7409210010 | Doc | 56.9% | CN | US | 2025-05-12 |

| 7409210050 | Doc | 56.9% | CN | US | 2025-05-12 |

| 7403210000 | Doc | 56.0% | CN | US | 2025-05-12 |

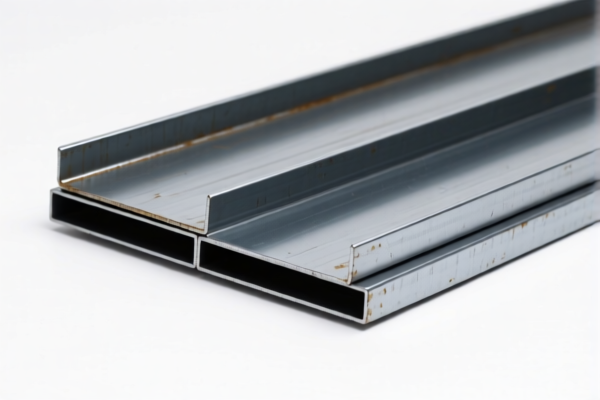

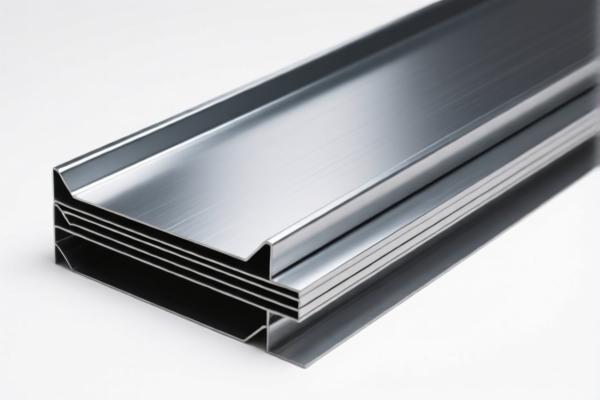

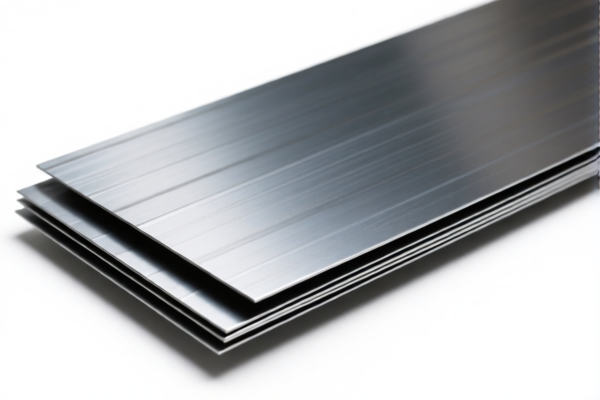

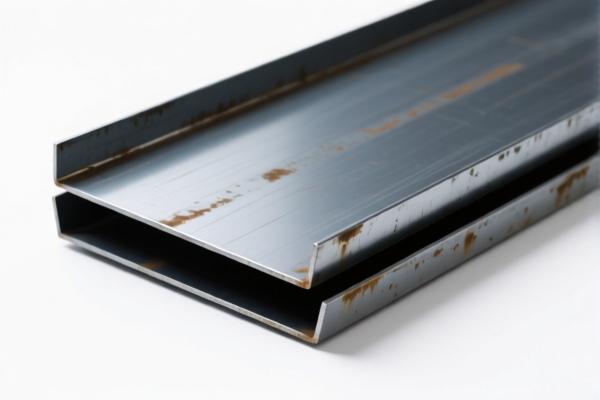

Brass Sheets

Brass sheets are flat pieces of metal alloy composed primarily of copper and zinc, with varying proportions determining specific characteristics. They are widely utilized across diverse applications due to their unique combination of properties.

Material Composition

The core components of brass sheets are:

- Copper (Cu): Typically constitutes 60-90% of the alloy, contributing to corrosion resistance, ductility, and electrical conductivity.

- Zinc (Zn): Generally ranges from 10-40%, influencing strength, machinability, and melting point.

- Other Elements: Small percentages of lead, tin, aluminum, manganese, or iron can be added to modify properties like strength, color, or corrosion resistance. The specific alloy designation (e.g., 260 brass, 360 brass) indicates the precise composition.

Properties

Key characteristics of brass sheets include:

- Corrosion Resistance: Superior to steel, particularly in marine environments.

- Ductility & Malleability: Easily formed, bent, and shaped.

- Machinability: Brass readily lends itself to cutting, drilling, and other machining operations.

- Electrical Conductivity: Good conductor of electricity, though lower than copper.

- Thermal Conductivity: Efficiently transfers heat.

- Acoustic Properties: Possesses favorable acoustic characteristics, used in musical instruments.

- Color: Typically golden-yellow, though color varies based on zinc content; can be polished to a bright finish.

Purpose & Function

Brass sheets serve a multitude of functions across various industries:

- Structural Components: Used in applications requiring moderate strength and corrosion resistance.

- Decorative Elements: Employed in architectural details, furniture, and artistic creations.

- Electrical Components: Used in connectors, terminals, and other electrical parts.

- Heat Exchangers: Utilized in radiators and other heat transfer systems.

- Musical Instruments: A primary material for brass instruments due to its acoustic properties and workability.

- Ammunition Casings: Some brass alloys are used in the manufacture of cartridge cases.

Usage Scenarios

Common applications include:

- Architecture: Roofing, cladding, decorative panels, door hardware.

- Automotive: Radiators, fuel tanks, decorative trim.

- Electronics: Connectors, terminals, shielding.

- Plumbing: Fittings, valves, fixtures.

- Marine: Propellers, fittings, valves.

- Musical Instruments: Trumpets, trombones, saxophones.

- Art & Craft: Sculptures, jewelry, decorative items.

- Stamping & Forming: Used in the production of various stamped parts.

Common Types

Brass sheets are categorized based on their alloy composition, each possessing unique characteristics:

- 260 Brass (Yellow Brass): Approximately 70% copper, 30% zinc. Excellent cold working properties, good ductility, commonly used for decorative applications.

- 360 Brass (Free-Cutting Brass): Approximately 60% copper, 40% zinc, with a small addition of lead. Superior machinability, widely used for screw machine parts.

- 385 Brass (Architectural Brass): Approximately 55% copper, 45% zinc. Good strength and corrosion resistance, often used for architectural applications.

- 410 Brass (Naval Brass): Approximately 60% copper, 40% zinc, with a small addition of tin. Excellent corrosion resistance, suitable for marine environments.

- 85-5 Brass (Red Brass): Approximately 85% copper, 15% zinc. Stronger and more corrosion resistant than yellow brass, used in plumbing and hardware.

Brass sheets fall under copper alloys, specifically copper-zinc base alloys. The following HS codes are relevant based on the provided information:

- 7409210010: Copper plates, sheets and strip, of a thickness exceeding 0.15 mm; Of copper-zinc base alloys (brass); In coils Of a thickness of 5 mm or more. This code applies to brass sheets that are thicker than 0.15 mm and supplied in coil form, with a thickness of 5 mm or greater.

- 7409210050: Copper plates, sheets and strip, of a thickness exceeding 0.15 mm; Of copper-zinc base alloys (brass); In coils Of a thickness of less than 5 mm; Of a width of 500 mm or more. This code applies to brass sheets thicker than 0.15 mm, supplied in coil form, with a thickness less than 5 mm and a width of 500 mm or more.

- 7403210000: Refined copper and copper alloys, unwrought (other than master alloys of heading 7405); Copper alloys; Copper-zinc base alloys (brass). This code covers unwrought brass alloys, meaning they are not further processed into specific shapes like sheets, plates, or coils.

HS Code Breakdown:

- 74: Refined copper. This chapter generally covers copper and articles thereof.

- 09: Copper plates, sheets and strip. This heading specifically covers flat-rolled products of copper.

- 21: Of copper-zinc base alloys (brass). This subheading narrows the classification to brass alloys.

- 00: Further specifies the form and dimensions of the brass products.

Important Note:

Regarding HS codes 7409210010 and 7409210050, the total tax rate is 56.9%, comprised of a 1.9% basic tariff, a 25.0% additional tariff, and a 30% additional tariff effective after April 2, 2025. HS code 7403210000 has a total tax rate of 56.0%, comprised of a 1.0% basic tariff, a 25.0% additional tariff, and a 30% additional tariff effective after April 2, 2025.

Customer Reviews

No reviews yet.