| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8442300150 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8442300110 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8456111010 | Doc | 58.5% | CN | US | 2025-05-12 |

| 8456119000 | Doc | 57.4% | CN | US | 2025-05-12 |

| 8485800000 | Doc | 57.5% | CN | US | 2025-05-12 |

| 8485909000 | Doc | 55.0% | CN | US | 2025-05-12 |

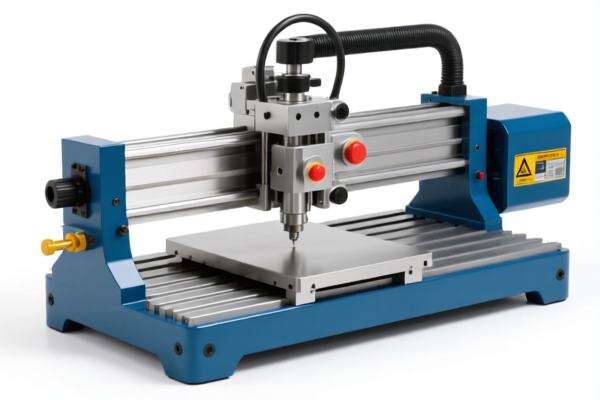

Laser Cutting Machine

A laser cutting machine is a computer-controlled manufacturing technology that utilizes a high-powered laser to cut materials. It delivers a focused laser beam which melts, burns, or vaporizes material, leaving an edge with a high-quality surface finish.

Materials

Laser cutting machines are versatile and can process a wide range of materials, including:

- Metals: Steel (carbon steel, stainless steel, mild steel), Aluminum, Titanium, Copper, Brass, Galvanized Steel.

- Non-Metals: Acrylic, Wood, Plastics (ABS, POM, Delrin, Polycarbonate), Fabric, Paper, Rubber, Leather, Stone, and composites. The suitability depends on the laser type (see below).

- Other: Some machines can also process materials like glass and ceramics with specialized setups.

Purpose & Function

The primary purpose of a laser cutting machine is to precisely cut complex shapes and designs from sheet or plate materials. Key functions include:

- Cutting: The core function, creating clean cuts through the material.

- Engraving: Lower power settings allow for surface marking and detailed engraving.

- Etching: Removing a thin layer of material to create a design.

- Perforation: Creating small holes in the material.

- Contour Cutting: Cutting along a defined path for intricate shapes.

Usage Scenarios

Laser cutting machines are used across numerous industries:

- Manufacturing: Automotive, Aerospace, Electronics - for component fabrication, prototyping, and production.

- Signage & Advertising: Creating signs, displays, and promotional items.

- Medical: Cutting surgical instruments and implants.

- Textile Industry: Cutting fabrics for clothing, upholstery, and industrial textiles.

- Art & Design: Creating intricate artwork, models, and decorative items.

- Education: Used in schools and universities for prototyping and design projects.

- Jewelry Making: Cutting and engraving precious metals and gemstones.

Common Types

Laser cutting machines are categorized based on the laser source used:

- CO₂ Laser: Most common type for non-metal materials (acrylic, wood, fabric). Relatively low cost, suitable for thicker materials. Wavelength: 10.6 micrometers.

- Fiber Laser: Ideal for metal cutting, marking, and engraving. Higher precision, faster cutting speeds, and lower maintenance compared to CO₂ lasers. Wavelength: 1.064 micrometers.

- Nd:YAG Laser: Versatile, can cut both metals and non-metals, but generally slower than Fiber lasers for metal cutting.

- Crystal Laser: Less common, used for specialized applications.

Key Components

- Laser Source: Generates the laser beam.

- Motion System (X/Y Axis): Precisely moves the laser head or the material.

- Control System: Software that controls the laser and motion system, often using CAD/CAM files.

- Optical System: Mirrors and lenses focus the laser beam.

- Assist Gas System: Provides gas (oxygen, nitrogen, argon) to assist in the cutting process, removing debris and protecting the lens.

- Exhaust System: Removes fumes and particulate matter generated during cutting.

Advantages

- High Precision: Accurate and repeatable cuts.

- Versatility: Can process a wide range of materials.

- Speed: Faster cutting speeds compared to traditional methods.

- Non-Contact Process: Minimizes material distortion.

- Complex Shapes: Capable of cutting intricate designs.

- Automation: Easily integrated into automated manufacturing systems.

Laser cutting machines fall under several classifications depending on their specific function and application. Here's a breakdown of relevant HS codes based on the provided information:

- 8456111010: This code covers machine tools for working any material by removal of material using laser or other light/photon beam processes, specifically those operated by laser and used for working metal and are numerically controlled. This would apply to laser cutting machines designed for precision metal fabrication.

- 8456119000: This code also covers machine tools for working any material by removal of material using laser or other light/photon beam processes, but applies to those operated by laser and are other than those for working metal. This would include laser cutting machines used on materials like wood, plastics, or acrylic.

- 8456111010 & 8456119000: Both codes fall under Chapter 84 (Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof) and Heading 8456 (Machine tools for working any material by removal of material, by laser or other light or photon beam, ultrasonic, electro-discharge, electro-chemical, electron-beam, ionic-beam or plasma arc processes; water-jet cutting machines). The subheading (845611) further specifies machines operated by laser or other light/photon beam processes.

Regarding HS code 8456111010 & 8456119000, the applicable tax rate is a base tariff of 3.5%, a surcharge of 25.0%, and a surcharge of 30.0% after April 2, 2025, resulting in a total tariff of 58.5% (for metal working) or 57.4% (for other materials).

Customer Reviews

No reviews yet.