| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 3918102000 | Doc | 60.3% | CN | US | 2025-05-12 |

| 3918901000 | Doc | 60.3% | CN | US | 2025-05-12 |

| 3926901000 | Doc | 40.9% | CN | US | 2025-05-12 |

| 3926909989 | Doc | 42.8% | CN | US | 2025-05-12 |

| 6304996020 | Doc | 33.2% | CN | US | 2025-05-12 |

| 6305900000 | Doc | 43.7% | CN | US | 2025-05-12 |

| 6305390000 | Doc | 45.9% | CN | US | 2025-05-12 |

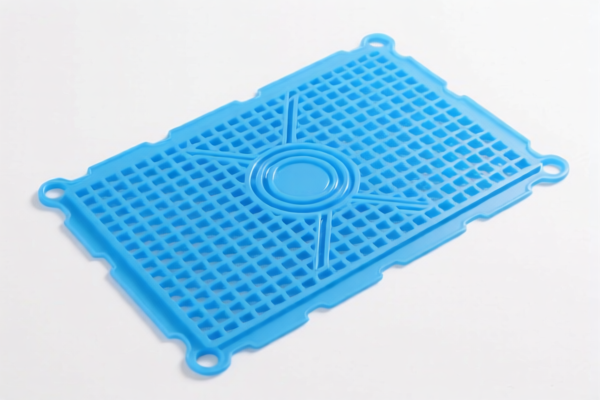

Plastic Floor Mat

A plastic floor mat is a protective covering typically used to safeguard flooring from damage, provide traction, and offer a degree of cushioning. They are manufactured from various plastic polymers and serve diverse purposes in residential, commercial, and industrial settings.

Material

Plastic floor mats are commonly produced from the following materials:

- Polyvinyl Chloride (PVC): A widely used, durable, and cost-effective plastic. PVC mats are available in numerous colors, patterns, and thicknesses. They exhibit good resistance to water, abrasion, and chemicals.

- Polypropylene (PP): A lightweight and flexible plastic known for its resistance to moisture, stains, and many chemicals. Often used for outdoor mats and interlocking tiles.

- Polyethylene (PE): A versatile plastic offering good impact resistance and flexibility. Frequently found in thinner, disposable mats or as a component in composite mats.

- Thermoplastic Elastomers (TPE): Combines the properties of rubber and plastic, providing flexibility, durability, and recyclability.

- Recycled Plastics: Increasingly common, utilizing post-consumer or post-industrial plastic waste to create environmentally friendly mats.

Purpose

The primary purposes of plastic floor mats include:

- Floor Protection: Preventing scratches, dents, and wear on underlying flooring materials (wood, tile, laminate, etc.).

- Slip Resistance: Providing traction to reduce the risk of slips and falls, particularly in wet or high-traffic areas.

- Dirt and Moisture Control: Trapping dirt, debris, and liquids to maintain cleaner floors and reduce maintenance.

- Aesthetic Enhancement: Adding color, pattern, and visual appeal to a space.

- Noise Reduction: Dampening sound transmission, particularly in areas with heavy foot traffic.

Function

Plastic floor mats function through several mechanisms:

- Physical Barrier: The mat itself acts as a protective layer against physical impact and abrasion.

- Friction: Textured surfaces increase friction, improving grip and reducing the likelihood of slipping.

- Liquid Absorption/Containment: Certain mat designs incorporate channels, reservoirs, or absorbent materials to trap liquids.

- Debris Trapping: Surface patterns and structures capture dirt and debris, preventing it from being tracked across the floor.

Usage Scenarios

Plastic floor mats are employed in a wide range of applications:

- Residential: Entryways, kitchens, bathrooms, hallways, under furniture.

- Commercial: Retail stores, offices, restaurants, hotels, schools, healthcare facilities.

- Industrial: Factories, warehouses, workshops, construction sites, laboratories.

- Outdoor: Patios, decks, walkways, playgrounds, vehicle access areas.

- Automotive: Car floor mats to protect the vehicle's interior.

Common Types

- Entryway Mats: Designed to trap dirt and moisture from shoes. Often ribbed or textured.

- Anti-Fatigue Mats: Provide cushioning to reduce strain on feet and legs during prolonged standing. Common in industrial and commercial settings.

- Chair Mats: Protect flooring under office chairs, allowing for smooth movement.

- Interlocking Tiles: Modular tiles that can be assembled to create custom-sized floor coverings.

- Runners: Long, narrow mats used in hallways, kitchens, or entryways.

- Outdoor/Patio Mats: Durable, weather-resistant mats designed for outdoor use.

- Diamond Plate Mats: Feature a raised diamond pattern for enhanced traction and durability.

- Logo Mats: Customized mats featuring company logos or branding.

- Gravel Mats: Designed for use under gravel driveways or walkways, providing stability and drainage.

Plastic floor mats can be categorized based on their composition (e.g., vinyl chloride polymers or other plastics), form (rolls or tiles), and intended use as floor coverings.

Here are the relevant HS codes based on the provided information:

- 3918102000: This HS code covers floor coverings of plastics made of polymers of vinyl chloride, whether self-adhesive or not, supplied in rolls or tiles. The basic duty is 5.3%, with an additional 25.0% surcharge, increasing to 30% after April 2, 2025, resulting in a total tariff of 60.3%. This is applicable to vinyl-based plastic floor mats.

- 3918901000: This HS code applies to floor coverings of plastics made of other plastics (excluding vinyl chloride polymers), whether self-adhesive or not, supplied in rolls or tiles. The basic duty is 5.3%, with an additional 25.0% surcharge, increasing to 30% after April 2, 2025, resulting in a total tariff of 60.3%. This is applicable to plastic floor mats not made of vinyl.

It is important to determine the specific plastic composition of the floor mat to correctly classify it under either 3918102000 or 3918901000.

Customer Reviews

No reviews yet.