| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 3926906010 | Doc | 59.2% | CN | US | 2025-05-12 |

| 3926909989 | Doc | 42.8% | CN | US | 2025-05-12 |

| 3901905501 | Doc | 61.5% | CN | US | 2025-05-12 |

| 3901909000 | Doc | 61.5% | CN | US | 2025-05-12 |

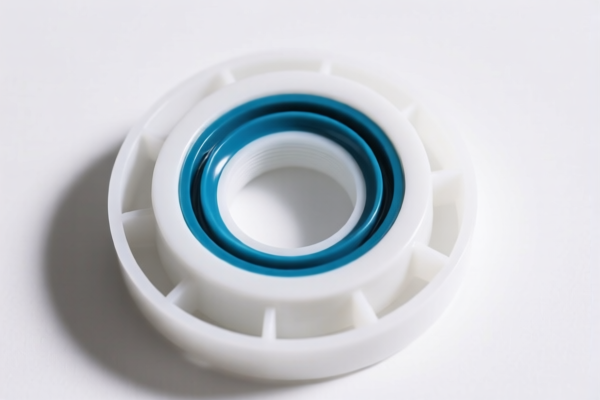

Plastic Welder

A plastic welder is a tool used to join two pieces of thermoplastic materials by melting the materials at the joining point. Unlike fusion welding which uses heat to create a molten pool, plastic welding relies on heating both surfaces to be bonded and then pressing them together, allowing the materials to cool and fuse.

Materials

Plastic welders are specifically designed for thermoplastics. Common materials welded include:

- Polypropylene (PP): Used in automotive parts, containers, and textiles.

- Polyethylene (PE): Commonly found in plastic bags, films, and pipes. Includes Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), and Ultra-High-Molecular-Weight Polyethylene (UHMWPE).

- Polyvinyl Chloride (PVC): Used in pipes, fittings, and window frames.

- Acrylonitrile Butadiene Styrene (ABS): Commonly used in automotive parts, toys, and housings.

- Polycarbonate (PC): Used in safety glasses, electronic components, and automotive parts.

- Polyurethane (PU): Used in foams, coatings, and adhesives.

It's crucial to ensure compatibility between the materials being welded. Welding dissimilar plastics can result in weak or brittle joints.

Purpose & Function

The primary purpose of a plastic welder is to create strong, durable, and often leak-proof joints between plastic components. They are used in a variety of applications where traditional welding methods are unsuitable due to the lower melting points and different properties of plastics. The function relies on:

- Heating: Generating sufficient heat to melt the plastic at the joining surfaces.

- Pressure: Applying consistent pressure to ensure proper fusion and eliminate air gaps.

- Filler Rods (optional): Adding filler material to reinforce the weld and fill gaps.

- Control: Maintaining precise temperature and pressure for optimal weld quality.

Usage Scenarios

Plastic welders are employed in numerous industries and applications:

- Automotive Repair: Repairing plastic bumpers, fenders, and interior components.

- Plumbing: Joining PVC pipes and fittings.

- Construction: Welding plastic sheets for roofing, siding, and tanks.

- Marine Repair: Repairing plastic boat hulls and components.

- DIY Projects: Fabricating or repairing plastic items around the home or workshop.

- Manufacturing: Production of plastic products requiring strong, permanent joints.

- Agricultural Applications: Repairing plastic tanks, containers, and irrigation systems.

Common Types

Several types of plastic welders are available, each suited for different applications and materials:

- Hot Air Welder: Uses a jet of hot air to melt the plastic. Suitable for welding larger sheets and fabrics. Offers good control and precision.

- Hot Plate Welder: Uses a heated plate to melt the plastic. Ideal for welding flat surfaces and producing consistent, high-quality welds.

- Extrusion Welder: Heats the plastic and extrudes molten plastic filler rod to create the weld. Commonly used for larger repairs and creating complex shapes.

- Ultrasonic Welder: Uses high-frequency ultrasonic vibrations to melt the plastic. Suitable for small, precise welds and automated applications.

- Socket Welder: Used specifically for welding plastic pipes and fittings. Consists of a heating tool and a socket to hold the components in place.

- Plastic Stapler: Uses heated staples to join plastic materials, often used for thinner plastics and quick repairs.

Based on the provided information, classifying “plastic welder” requires careful consideration of its components and function. Here’s a breakdown of potentially relevant HS codes:

-

3926906010: This code covers “Other articles of plastics and articles of other materials of headings 3901 to 3914: Other: Belting and belts, for machinery: Other Synchronous belts”. While a plastic welder isn’t a belt, it is machinery constructed from plastics and other materials. This code applies if the welder incorporates belts in its mechanism. The total tax rate is 59.2%, comprised of a 4.2% base tariff, a 25.0% additional tariff, and a 30% additional tariff effective April 2, 2025.

-

3926909989: This code is for “Other articles of plastics and articles of other materials of headings 3901 to 3914: Other: Other”. This is a broad category for plastic articles not specifically classified elsewhere. If the plastic welder doesn’t fall into a more specific category within 3926, this code may be applicable. The total tax rate is 42.8%, consisting of a 5.3% base tariff and a 7.5% additional tariff, increasing to 30% on April 2, 2025.

-

3901905501: This code covers “Polymers of ethylene, in primary forms: Other: Other: Ethylene copolymers”. If the plastic welder is primarily constructed from ethylene copolymers, this code could be relevant. The total tax rate is 61.5%, with a 6.5% base tariff and a 25.0% additional tariff, rising to 30% on April 2, 2025.

-

3901909000: This code is for “Polymers of ethylene, in primary forms: Other: Other: Other”. If the plastic welder is made of other ethylene polymers not specifically defined, this code might apply. The total tax rate is 61.5%, consisting of a 6.5% base tariff and a 25.0% additional tariff, increasing to 30% on April 2, 2025.

According to the provided reference material, the HS code options related to 'plastic welder' are limited, with only the following 4 found.

It is important to note that the final HS code classification will depend on the specific materials used in the construction of the plastic welder and its intended function.

Customer Reviews

No reviews yet.