| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 3919102055 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3919905060 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3921904010 | Doc | 34.2% | CN | US | 2025-05-12 |

| 3921904090 | Doc | 34.2% | CN | US | 2025-05-12 |

| 5603110010 | Doc | 55.0% | CN | US | 2025-05-12 |

| 5603110070 | Doc | 55.0% | CN | US | 2025-05-12 |

| 5602101000 | Doc | 67.0% | CN | US | 2025-05-12 |

| 5602903000 | Doc | 55.0% | CN | US | 2025-05-12 |

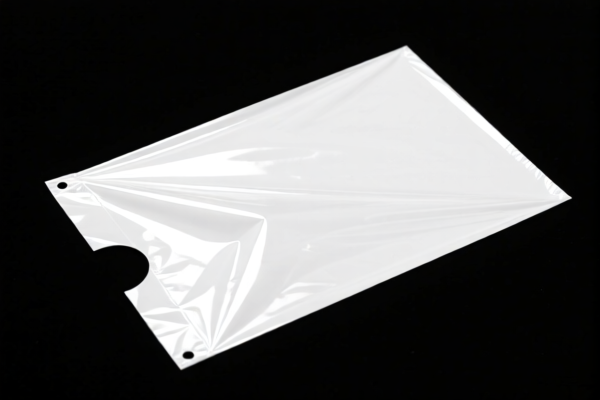

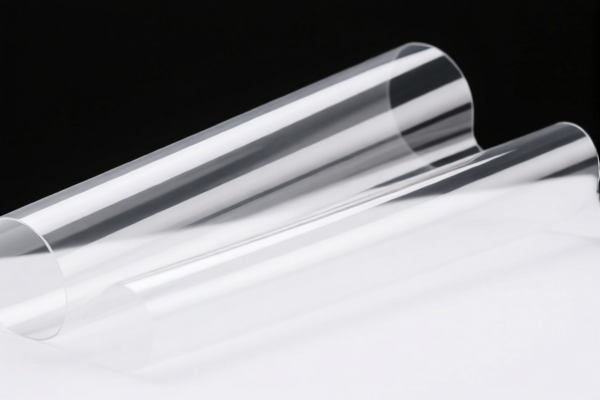

Protective Film

A protective film is a thin layer of material applied to the surface of an object to shield it from damage, scratches, dirt, chemicals, and other forms of wear and tear. These films are typically temporary, though some are designed for longer-term protection.

Materials

Protective films are manufactured from a variety of materials, each offering different properties:

- Polyethylene (PE): Commonly used for general protection due to its low cost and flexibility. Often used in construction and packaging.

- Polypropylene (PP): Offers higher temperature resistance and strength than PE. Frequently found in automotive applications and furniture protection.

- Polyurethane (PU): Known for its excellent abrasion resistance and flexibility. Used in screen protectors for electronic devices and automotive paint protection.

- Polyvinyl Chloride (PVC): Durable and chemical-resistant, but less environmentally friendly than other options. Used in industrial applications and some packaging.

- Polyester (PET): Offers high clarity and strength. Common in screen protectors and for protecting delicate surfaces.

- Acrylic: Provides good UV resistance and clarity. Used in displays and automotive applications.

- Thermoplastic Polyurethane (TPU): Combines the properties of PU and PP, offering flexibility, abrasion resistance, and good impact resistance. Popular for phone cases and screen protectors.

Purpose and Function

The primary purpose of a protective film is to prevent damage to the underlying surface. This is achieved through several functions:

- Scratch Resistance: The film absorbs minor scratches and abrasions, preserving the original surface.

- Impact Absorption: Some films offer a degree of impact resistance, protecting against dents and cracks.

- UV Protection: Certain films block harmful UV rays, preventing fading and discoloration.

- Chemical Resistance: Films can protect against spills, solvents, and other corrosive substances.

- Dust and Dirt Barrier: Protective films create a barrier against dust, dirt, and other contaminants.

- Retention of Appearance: Helps maintain the original look and finish of the protected surface.

Usage Scenarios

Protective films are utilized across a wide range of industries and applications:

- Electronics: Screen protectors for smartphones, tablets, laptops, and televisions.

- Automotive: Paint protection film (PPF) to shield vehicle exteriors from scratches, chips, and environmental damage. Interior surface protection.

- Construction: Temporary protection for windows, doors, floors, and other surfaces during building and renovation.

- Packaging: Protecting goods during shipping and storage.

- Furniture: Protecting surfaces from scratches, spills, and wear.

- Displays and Signage: Protecting graphics and surfaces from vandalism and abrasion.

- Medical: Protective coverings for equipment and surfaces.

Common Types

- Screen Protectors: Typically made of PET or TPU, available in various thicknesses and finishes (glossy, matte, anti-glare).

- Paint Protection Film (PPF): A thicker, more durable film designed for automotive paint protection. Often self-healing.

- Temporary Protective Films: Low-cost PE films used for short-term protection during construction or shipping.

- Self-Adhesive Films: Films with an adhesive backing for easy application to various surfaces.

- Anti-Fingerprint Films: Films with a coating to reduce fingerprints and smudges.

- Privacy Films: Films that limit the viewing angle, protecting sensitive information.

- Hydrogel Films: A newer type of screen protector offering high flexibility and self-healing properties.

The declared goods, “protective film,” fall under several classifications based on material and application. Here's a breakdown of relevant HS codes:

- 3919.10.20.55: This HS code covers self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls, specifically those in rolls of a width not exceeding 20 cm. The tax detail indicates a basic tariff of 5.8%, an additional tariff of 25.0%, and an additional tariff of 30.0% after April 2, 2025, resulting in a total tax of 60.8%.

- 3919.90.50.60: This HS code also covers self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls, but categorized as 'Other'. Similar to the previous code, it has a basic tariff of 5.8%, an additional tariff of 25.0%, and an additional tariff of 30.0% after April 2, 2025, totaling 60.8% tax.

- 3921.90.40.10: This HS code covers other plates, sheets, film, foil and strip, of plastics, specifically flexible reinforced with paper. The tax detail shows a basic tariff of 4.2%, no additional tariff currently, but a 30.0% additional tariff after April 2, 2025, resulting in a total tax of 34.2%.

- 3921.90.40.90: This HS code covers other plates, sheets, film, foil and strip, of plastics, categorized as 'Flexible Other'. It shares the same tax structure as the previous code: 4.2% basic tariff, no current additional tariff, and 30.0% after April 2, 2025, for a total of 34.2%.

It's important to note that the applicable HS code depends on the specific composition and characteristics of the protective film.

Regarding these HS codes, please note the potential for tariff changes after April 2, 2025, with additional tariffs increasing to 30.0% for several classifications.

Customer Reviews

No reviews yet.