| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 7305191030 | Doc | 30.0% | CN | US | 2025-05-12 |

| 7305191060 | Doc | 30.0% | CN | US | 2025-05-12 |

| 7304110020 | Doc | 30.0% | CN | US | 2025-05-12 |

| 7304110020 | Doc | 30.0% | CN | US | 2025-05-12 |

| 7608100030 | Doc | 35.7% | CN | US | 2025-05-12 |

| 7608100090 | Doc | 35.7% | CN | US | 2025-05-12 |

| 7610900080 | Doc | 85.7% | CN | US | 2025-05-12 |

| 7610900060 | Doc | 85.7% | CN | US | 2025-05-12 |

| 9406900190 | Doc | 82.9% | CN | US | 2025-05-12 |

| 9406900130 | Doc | 82.9% | CN | US | 2025-05-12 |

| 8413702005 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8413919096 | Doc | 55.0% | CN | US | 2025-05-12 |

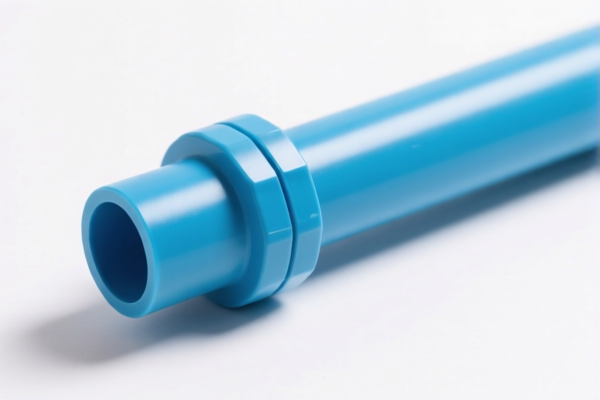

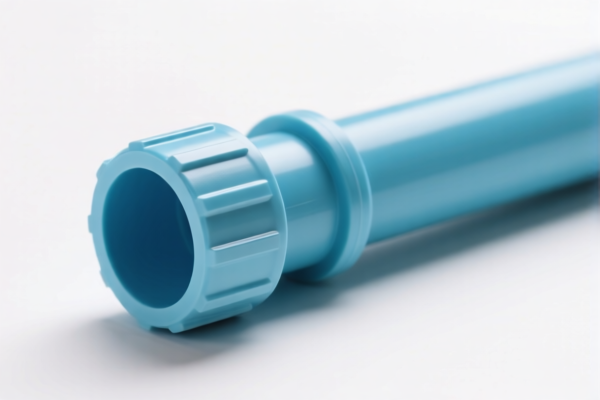

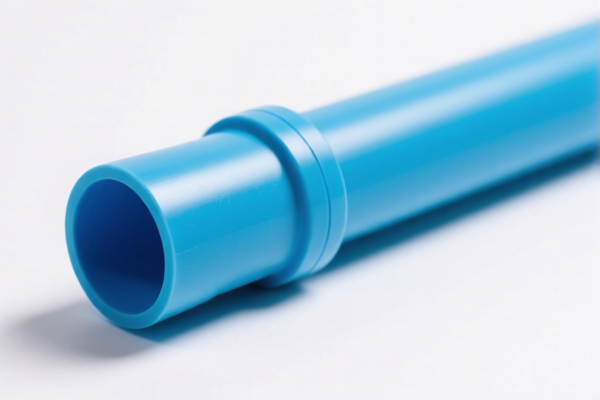

Pumping Pipe

Pumping pipe, also known as slurry pipe or dredge pipe, is a specialized type of piping designed for the conveyance of abrasive or corrosive materials in a slurry form. These pipes are integral to various industries involving the transport of solids mixed with liquids.

Material

Pumping pipes are constructed from a variety of materials chosen based on the properties of the slurry being transported and the operational environment. Common materials include:

- High-Density Polyethylene (HDPE): Lightweight, flexible, and resistant to many chemicals. Often used for temporary installations and lower-pressure applications.

- Steel: Provides high strength and durability, suitable for high-pressure and high-abrasion applications. Common steel grades include carbon steel (often with linings) and stainless steel (for corrosion resistance).

- Rubber: Offers excellent abrasion resistance and flexibility, commonly used for lining steel pipes or as a standalone material for lower-pressure applications.

- Composite Materials: Combining the benefits of multiple materials, offering high strength, abrasion resistance, and corrosion resistance.

Purpose

The primary purpose of pumping pipe is to efficiently and reliably transport slurries over various distances and elevations. This includes:

- Moving abrasive materials: Such as sand, gravel, and rock in dredging operations.

- Transporting corrosive fluids: Like chemicals, wastewater, and mining tailings.

- Discharging pumped materials: From pumps to designated locations.

Function

Pumping pipes function by providing a contained pathway for the slurry, resisting internal pressure, and minimizing wear and tear from the abrasive or corrosive materials. Key functional aspects include:

- Pressure Resistance: Pipes are designed to withstand the internal pressure generated by the pump and the weight of the slurry.

- Abrasion Resistance: Materials and linings are selected to resist erosion caused by the solid particles within the slurry.

- Corrosion Resistance: Materials are chosen to prevent chemical degradation and leakage.

- Flexibility: Some pipes, particularly HDPE, offer flexibility to accommodate ground movement or changes in direction.

- Leak Prevention: Joints and connections are designed to prevent leakage of the slurry.

Usage Scenarios

Pumping pipes are utilized across a broad range of industries and applications:

- Dredging: Transporting dredged material (sand, silt, gravel) from the seabed or riverbeds.

- Mining: Moving tailings, slurries of ore, and process water.

- Wastewater Treatment: Conveying sludge and other waste materials.

- Agriculture: Irrigation and fertilizer distribution.

- Construction: Transporting concrete slurry and other construction materials.

- Oil and Gas: Transferring drilling mud and produced water.

- Power Generation: Transporting ash slurry.

Common Types

Pumping pipes are categorized based on their material, construction, and connection methods:

- HDPE Pipe: Lightweight, flexible, often used with flanged or butt fusion connections.

- Steel Pipe (Carbon Steel): Heavy-duty, often with rubber linings, connected by flanges, welded joints, or quick couplings.

- Steel Pipe (Stainless Steel): Corrosion-resistant, used in demanding chemical environments, connected similarly to carbon steel pipe.

- Rubber Hose: Flexible, abrasion-resistant, often used for temporary installations or short distances, connected by clamps or quick couplings.

- Floating Pipe: Designed to float on the surface of water, commonly used in dredging applications.

- Flexible Pipe: Constructed with multiple layers of materials to provide flexibility and resistance to bending and stress.

- Dredge Pipe (Spirally Wound): Reinforced with steel wire, offering high strength and flexibility for dredging operations.

Pumping pipe generally refers to tubes used for conveying fluids, often in oil and gas pipelines or industrial applications. Based on the provided information, several HS codes may be relevant depending on the specific characteristics of the pipe.

Here are the relevant HS codes:

- 7305191030: This code covers other tubes and pipes (welded, riveted, or similarly closed) with circular cross-sections exceeding 406.4 mm in external diameter, specifically line pipe used for oil or gas pipelines, made of iron or non-alloy steel with an external diameter exceeding 406.4 mm but not exceeding 609.6 mm. The total tax rate is 30.0%.

- 7305191060: This code also covers other tubes and pipes (welded, riveted, or similarly closed) with circular cross-sections exceeding 406.4 mm in external diameter, specifically line pipe used for oil or gas pipelines, made of iron or non-alloy steel with an external diameter exceeding 609.6 mm. The total tax rate is 30.0%.

- 7304110020: This code covers tubes, pipes, and hollow profiles, seamless, of iron (other than cast iron) or steel, specifically line pipe used for oil or gas pipelines, of stainless steel with an outside diameter not exceeding 114.3 mm. The total tax rate is 30.0%.

- 8413702005: This code covers pumps for liquids, whether or not fitted with a measuring device; liquid elevators; part thereof, specifically other centrifugal pumps, single-stage, single-suction, close-coupled, with discharge outlet under 5.08 cm in diameter. The total tax rate is 55.0%.

Important Considerations:

- The HS code selection depends on the pipe's material (iron, steel, stainless steel, or aluminum), manufacturing process (welded, seamless), diameter, and intended use (oil/gas pipeline vs. general pumping).

- If the pumping pipe is part of a pump assembly, HS code 8413702005 or 8413919096 (parts of pumps) may be more appropriate.

- For HS codes 7305191030 and 7305191060, the pipe must be specifically identified as "line pipe" used for oil or gas pipelines.

- HS code 8413702005 applies to pumps with a discharge outlet under 5.08 cm in diameter.

Customer Reviews

No reviews yet.