| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 4008210000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 4008292000 | Doc | 57.9% | CN | US | 2025-05-12 |

| 4005910000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 4005990000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 3913901000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 3913905000 | Doc | 61.5% | CN | US | 2025-05-12 |

| 3926904510 | Doc | 58.5% | CN | US | 2025-05-12 |

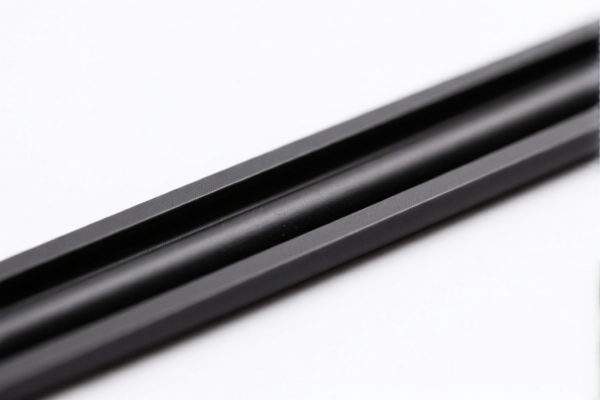

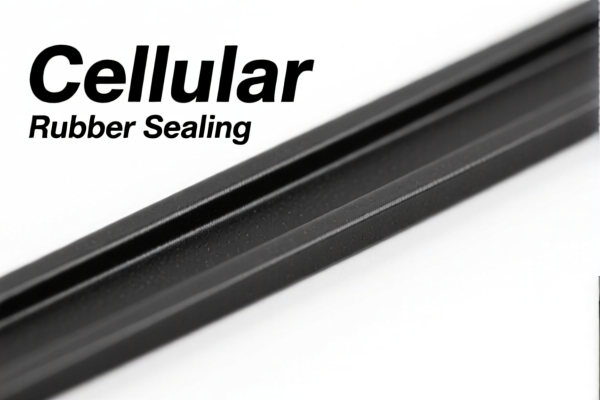

Rubber Seal Strip

A rubber seal strip (also known as a rubber gasket, sealing strip, or weatherstripping) is a flexible component designed to block out unwanted substances – typically air, water, dust, and noise – from entering a space. It is a crucial element in a wide range of applications, from automotive manufacturing to construction and household appliances.

Material

The primary material is, as the name suggests, rubber. However, various rubber compounds are used, each offering specific properties:

- Neoprene (Polychloroprene): Offers excellent resistance to weather, ozone, chemicals, and abrasion. Common in automotive and general-purpose applications.

- EPDM (Ethylene Propylene Diene Monomer): Superior resistance to weathering, ozone, UV radiation, and heat. Frequently used in outdoor applications and automotive weatherstripping.

- Silicone: Exhibits excellent temperature resistance (both high and low), flexibility, and resistance to chemicals. Used in high-temperature applications, food-grade seals, and medical devices.

- Nitrile (Buna-N): Resistant to oils, fuels, and chemicals. Commonly found in automotive seals and industrial applications.

- PVC (Polyvinyl Chloride): A cost-effective option, offering good resistance to water and chemicals, but less flexible than other options.

- TPE (Thermoplastic Elastomer): Combines the properties of rubber and plastic, offering good flexibility, weather resistance, and recyclability.

Beyond the primary rubber, reinforcement materials like fabric or metal can be embedded to increase strength, stability, and durability.

Purpose

The primary purpose of a rubber seal strip is to create a barrier against:

- Air Leaks: Improving energy efficiency by preventing drafts and reducing heating/cooling costs.

- Water Ingress: Protecting interiors from moisture damage, corrosion, and mold growth.

- Dust and Debris: Preventing the entry of contaminants that can damage sensitive components or affect air quality.

- Noise Reduction: Dampening sound transmission and improving acoustic performance.

- Vibration Dampening: Reducing noise and wear caused by vibrations.

Function

Rubber seal strips function by:

- Compression: They are designed to be compressed when installed, creating a tight seal against mating surfaces.

- Conformability: Their flexibility allows them to conform to irregular shapes and surfaces, ensuring a complete seal.

- Elasticity: They maintain their shape and sealing properties over time due to their elastic nature.

- Friction: They create friction against the mating surface, further enhancing the seal.

Usage Scenarios

- Automotive: Door seals, window seals, trunk seals, hood seals, windshield seals.

- Construction: Window and door seals, expansion joint seals, pipe seals, roofing seals.

- Appliances: Refrigerator door seals, oven door seals, washing machine seals, dishwasher seals.

- HVAC: Duct seals, window unit seals.

- Marine: Hatch seals, window seals, hull seals.

- Industrial: Machinery seals, conveyor seals, pipeline seals.

Common Types

- Solid Rubber Strips: Simple, cost-effective strips used for basic sealing applications.

- Foam Rubber Strips: Lightweight and provide good cushioning and sealing. Often used in interior applications.

- Extruded Rubber Strips: Manufactured by forcing rubber through a die, creating complex shapes and profiles. Most common type.

- Hollow Rubber Strips: Offer good cushioning and sealing, and can be used for edge protection.

- Adhesive-Backed Rubber Strips: Feature a self-adhesive backing for easy installation.

- Magnetic Rubber Strips: Utilize a magnetic strip for attachment to metal surfaces.

- Brush Seals: Feature bristles that create a barrier against air, dust, and debris. Commonly used in doors and windows.

- U-shaped/V-shaped Seals: Designed to fit over edges and create a tight seal.

Rubber seal strip can be categorized based on its composition, manufacturing process (vulcanized or unvulcanized), and specific application. The following HS codes may be relevant:

- 4008210000: This code covers plates, sheets, and strip of vulcanized rubber other than hard rubber, specifically of noncellular rubber. This is applicable if the rubber seal strip is vulcanized, not hard rubber, and has a noncellular structure. The total tax rate is 55.0%, comprised of a 0.0% base tariff, a 25.0% additional tariff, and a 30.0% additional tariff effective after April 2, 2025.

- 4008292000: This code also covers plates, sheets, strip, rods and profile shapes of vulcanized rubber other than hard rubber, but specifically for other profile shapes of noncellular rubber. If the rubber seal strip is a profile shape, this code may be applicable. The total tax rate is 57.9%, comprised of a 2.9% base tariff, a 25.0% additional tariff, and a 30.0% additional tariff effective after April 2, 2025.

- 4005910000: This code covers compounded rubber, unvulcanized, in primary forms or in plates, sheets or strip, specifically for other plates, sheets, and strip. If the rubber seal strip is unvulcanized, this code may be applicable. The total tax rate is 55.0%, comprised of a 0.0% base tariff, a 25.0% additional tariff, and a 30.0% additional tariff effective after April 2, 2025.

- 3926904510: This code covers other articles of plastics and articles of other materials of headings 3901 to 3914, specifically for gaskets, washers and other seals, including O-Rings. If the rubber seal strip functions as a gasket or seal, this code may be applicable. The total tax rate is 58.5%, comprised of a 3.5% base tariff, a 25.0% additional tariff, and a 30.0% additional tariff effective after April 2, 2025.

It is important to determine whether the rubber seal strip is vulcanized or unvulcanized, its cellular structure (cellular or noncellular), and its specific function (e.g., gasket, seal, strip) to select the most appropriate HS code.

Customer Reviews

No reviews yet.