| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8460390010 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8460904060 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8461508090 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8461508090 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8474200010 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8474200050 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6805100000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6805200000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6815910071 | Doc | 55.0% | CN | US | 2025-05-12 |

| 6815994170 | Doc | 55.0% | CN | US | 2025-05-12 |

Sandpaper Machine

A sandpaper machine is a power tool used to smooth surfaces, remove material, and shape objects using abrasive sandpaper. These machines utilize varying mechanisms to move sandpaper across a workpiece, significantly reducing manual effort and improving efficiency compared to hand sanding.

Materials

Sandpaper machines are primarily constructed from:

- Metal: Commonly steel or aluminum alloys for the housing, motor casing, and structural components, providing durability and stability.

- Plastic: Often used for handles, guards, and some housing parts to reduce weight and provide insulation.

- Rubber: Used in vibration dampening components and sometimes for grips.

- Electrical Components: Motors, switches, wiring, and sometimes electronic speed control systems.

- Abrasive Materials: Sandpaper itself, typically consisting of abrasive particles (aluminum oxide, silicon carbide, garnet, zirconia alumina, ceramic) bonded to a paper, cloth, or film backing.

Purpose & Function

The primary purpose of a sandpaper machine is to modify the surface of a material through abrasion. Functions include:

- Smoothing: Removing imperfections like scratches, dents, and tool marks.

- Material Removal: Aggressively removing layers of wood, metal, plastic, or other materials.

- Shaping: Contouring and refining the form of an object.

- Finishing: Preparing surfaces for painting, staining, or other coatings.

- Polishing: Achieving a smooth, glossy finish (often with finer grits of sandpaper).

Usage Scenarios

Sandpaper machines are used in a wide range of applications:

- Woodworking: Furniture making, cabinet construction, flooring installation, and general wood shaping.

- Metalworking: Deburring, rust removal, weld preparation, and surface finishing.

- Automotive Repair: Body panel preparation, paint removal, and rust treatment.

- Construction: Smoothing drywall, preparing surfaces for painting, and shaping materials.

- DIY Projects: Home repairs, furniture restoration, and craft projects.

Common Types

Several types of sandpaper machines cater to different needs:

- Belt Sanders: Utilize a continuous loop of sandpaper moving around a drum. Effective for rapid material removal and leveling. Available in benchtop and portable models.

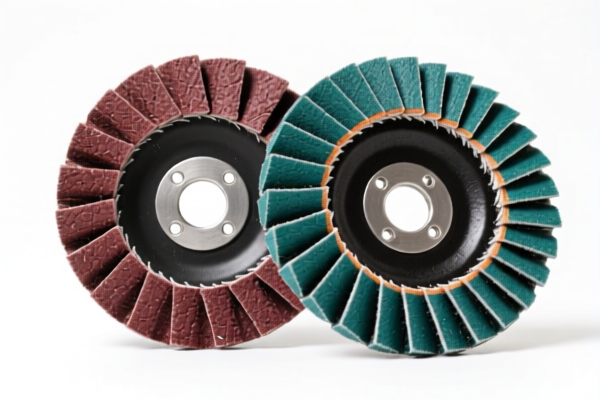

- Disc Sanders: Employ a rotating disc covered in sandpaper. Suitable for contouring, shaping, and smoothing. Variations include benchtop, pedestal, and angle grinders with sanding discs.

- Orbital Sanders (Random Orbital Sanders): Move in both circular and oscillating motions, preventing swirl marks and providing a smoother finish. Common for wood finishing and general sanding.

- Detail Sanders (Corner Sanders/Mouse Sanders): Small, lightweight sanders designed for reaching tight corners and intricate areas.

- Drum Sanders: Large benchtop machines with a rotating drum covered in sandpaper. Used for sanding large, flat surfaces like flooring.

- Multi-Sander: Versatile tools that combine multiple sanding functions in a single unit (e.g., orbital, detail, edge).

Safety Considerations

- Eye Protection: Always wear safety glasses or a face shield to protect against dust and debris.

- Respiratory Protection: Use a dust mask or respirator to prevent inhalation of abrasive particles.

- Hearing Protection: Sandpaper machines can be loud; wear earplugs or earmuffs.

- Proper Grip & Stance: Maintain a firm grip and stable stance to control the tool.

- Cord Management: Keep the power cord away from the sanding surface and moving parts.

- Material Compatibility: Use appropriate sandpaper grit and type for the material being sanded.

Sandpaper machines fall under several potential classifications based on their function and application. Here's a breakdown of relevant HS codes based on the provided information:

- 8460390010: Machine tools for deburring, sharpening, grinding, honing, lapping, polishing or otherwise finishing metal or cermets by means of grinding stones, abrasives or polishing products, other than gear cutting, gear grinding or gear finishing machines of heading 8461. This includes sharpening (tool or cutter grinding) machines, specifically Other Used or rebuilt. This code applies if the machine is used for finishing metal or cermets using abrasives like sandpaper. The base tariff is 4.4%, with an additional 25.0% surcharge, increasing to 30.0% after April 2, 2025, resulting in a total tariff of 59.4%.

- 8460904060: Machine tools for deburring, sharpening, grinding, honing, lapping, polishing or otherwise finishing metal or cermets by means of grinding stones, abrasives or polishing products, other than gear cutting, gear grinding or gear finishing machines of heading 8461. This covers Other numerically controlled machines. If the sandpaper machine is numerically controlled, this HS code is applicable, with the same tariff structure as 8460390010 (59.4% total).

- 6805100000: Natural or artificial abrasive powder or grain, on a base of textile material, of paper, of paperboard or of other materials, whether or not cut to shape or sewn or otherwise made up: On a base of woven textile fabric only. This code applies if the machine produces sandpaper with a woven textile fabric base. The tariff is 0.0% base rate plus a 25.0% surcharge, increasing to 30.0% after April 2, 2025, for a total of 55.0%.

- 6805200000: Natural or artificial abrasive powder or grain, on a base of textile material, of paper, of paperboard or of other materials, whether or not cut to shape or sewn or otherwise made up: On a base of paper or paperboard only. This code applies if the machine produces sandpaper with a paper or paperboard base. The tariff structure is identical to 6805100000 (55.0% total).

- 8474200010: Machinery for sorting, screening, separating, washing, crushing, grinding, mixing or kneading earth, stone, ores or other mineral substances, in solid (including powder or paste) form; machinery for agglomerating, shaping or molding solid mineral fuels, ceramic paste, unhardened cements, plastering materials or other mineral products in powder or paste form; machines for forming foundry molds of sand; parts thereof: Crushing or grinding machines Portable. If the machine is portable and used for grinding mineral substances, this code may be applicable, with a 0.0% base rate and a 25.0% surcharge (increasing to 30.0% after April 2, 2025), resulting in a 55.0% total tariff.

- 8474200050: Machinery for sorting, screening, separating, washing, crushing, grinding, mixing or kneading earth, stone, ores or other mineral substances, in solid (including powder or paste) form; machinery for agglomerating, shaping or molding solid mineral fuels, ceramic paste, unhardened cements, plastering materials or other mineral products in powder or paste form; machines for forming foundry molds of sand; parts thereof: Crushing or grinding machines Stationary: Crushing. If the machine is stationary and used for crushing mineral substances, this code may be applicable, with a 0.0% base rate and a 25.0% surcharge (increasing to 30.0% after April 2, 2025), resulting in a 55.0% total tariff.

It is important to determine the precise function of the machine (metal finishing, abrasive production, mineral processing) and whether it is numerically controlled, portable, or stationary to select the correct HS code.

Customer Reviews

No reviews yet.