| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 3919905060 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3919905040 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3921904010 | Doc | 34.2% | CN | US | 2025-05-12 |

| 3921904090 | Doc | 34.2% | CN | US | 2025-05-12 |

| 8544499000 | Doc | 58.9% | CN | US | 2025-05-12 |

| 9001200000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 9001909000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8548000000 | Doc | 55.0% | CN | US | 2025-05-12 |

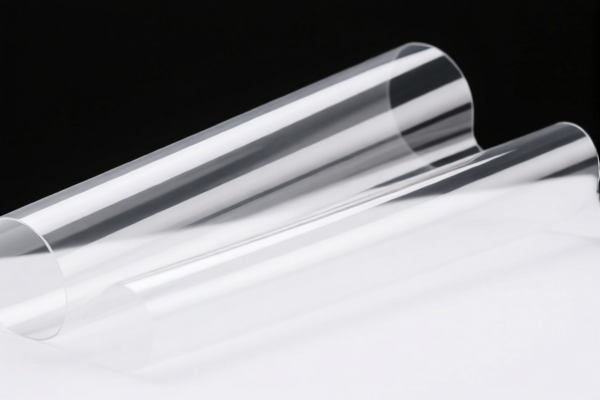

Shielding Film

Shielding film refers to a thin polymeric material incorporating conductive elements designed to block electromagnetic interference (EMI), radio frequency interference (RFI), or electrostatic discharge (ESD). It functions as a barrier against unwanted energy transmission, protecting sensitive electronic components or spaces.

Material Composition:

- Polymeric Base: Common polymers include polyester (PET), polycarbonate (PC), polyvinyl chloride (PVC), and polyethylene terephthalate (PET). The base material provides flexibility, durability, and desired optical properties.

- Conductive Layer: This is the core component providing the shielding effect. Common conductive materials include:

- Copper: Offers excellent conductivity and is widely used. Often applied as thin layers, meshes, or foils.

- Nickel: Provides good corrosion resistance and shielding performance.

- Silver: Exhibits the highest conductivity but is more expensive.

- Aluminum: Lightweight and cost-effective, but with lower conductivity than copper or silver.

- Carbon-based materials: Such as carbon nanotubes or graphene, offer lightweight and flexible shielding solutions.

- Conductive polymers: Like polyaniline or polypyrrole, provide inherent conductivity and flexibility.

- Adhesive: Often incorporated for ease of application and secure bonding to the target surface. Adhesive types vary based on the application requirements (e.g., conductive, non-conductive, temperature resistance).

Purpose & Function:

- EMI/RFI Shielding: Prevents electromagnetic or radio frequency signals from entering or exiting a device or enclosure, minimizing interference with other electronic systems or preventing data breaches.

- ESD Protection: Dissipates static electricity, preventing damage to sensitive electronic components during handling, storage, or operation.

- Signal Isolation: Blocks unwanted signal coupling between different components or circuits.

- Optical Clarity: Some films are designed to be transparent, allowing for use in displays, touch screens, or windows without compromising visibility.

Usage Scenarios:

- Electronics Manufacturing: Protecting circuit boards, components, and enclosures during assembly and testing.

- Data Security: Shielding rooms, servers, and devices to prevent eavesdropping or data theft.

- Automotive Industry: Protecting electronic control units (ECUs) and sensors from interference.

- Aerospace & Defense: Shielding critical avionics and communication systems.

- Medical Devices: Protecting sensitive electronic components in diagnostic and monitoring equipment.

- Window Films: Shielding buildings or vehicles from electromagnetic radiation.

- Touch Screens & Displays: Providing EMI shielding while maintaining optical clarity and touch sensitivity.

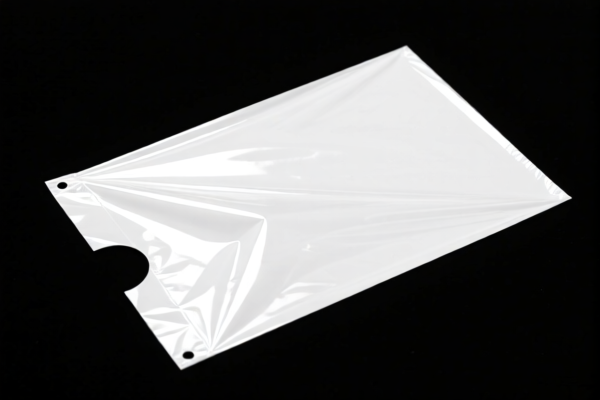

- Packaging: Protecting sensitive components during shipping and storage.

Common Types:

- Copper Foil Tape: A widely used, cost-effective shielding solution for general-purpose applications.

- Nickel-Copper Foil Tape: Offers improved corrosion resistance compared to pure copper tape.

- Conductive Fabric: Flexible and conformable, suitable for complex shapes and applications requiring high shielding effectiveness.

- PET Films with Conductive Coatings: Provide excellent optical clarity and are used in displays and touch screens.

- Polycarbonate Films with Conductive Coatings: Offer high impact resistance and are used in demanding applications.

- ESD Bags: Used for storing and transporting sensitive electronic components, providing both shielding and antistatic protection.

- Shielding Gaskets: Used to create a conductive seal between components or enclosures.

- Wire Mesh Shielding: Offers high shielding effectiveness and is used in applications requiring high levels of protection.

Shielding film can be categorized based on its material composition and application. The following HS codes may be relevant:

- 3919905060: This code covers self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls, categorized as "Other: Other". This is applicable if the shielding film is made of plastic and has a self-adhesive backing. The total tax rate is 60.8%, comprising a 5.8% base tariff and a 25.0% additional tariff, increasing to 30.0% after April 2, 2025.

- 3921904090: This code applies to other plates, sheets, film, foil and strip, of plastics, specifically categorized as "Other: Other: Flexible Other". If the shielding film is made of plastic but isn’t self-adhesive and is flexible, this code may be suitable. The total tax rate is 34.2%, consisting of a 4.2% base tariff and a 30.0% additional tariff after April 2, 2025.

- 8548000000: This code covers electrical parts of machinery or apparatus, not specified or included elsewhere. If the shielding film functions as an electrical component (e.g., EMI shielding), this code could be applicable. The total tax rate is 55.0%, consisting of a 25.0% additional tariff and a 30.0% additional tariff after April 2, 2025.

It is important to determine the precise material composition and function of the shielding film to select the most appropriate HS code. If the shielding film is made of plastic and has a self-adhesive backing, HS code 3919905060 is likely the most suitable. If it is a flexible plastic film without adhesive, HS code 3921904090 may be more appropriate. If it functions as an electrical component, HS code 8548000000 should be considered.

Customer Reviews

No reviews yet.