| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8309900090 | Doc | 57.6% | CN | US | 2025-05-12 |

| 3923500000 | Doc | 60.3% | CN | US | 2025-05-12 |

| 3919102030 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3919905040 | Doc | 60.8% | CN | US | 2025-05-12 |

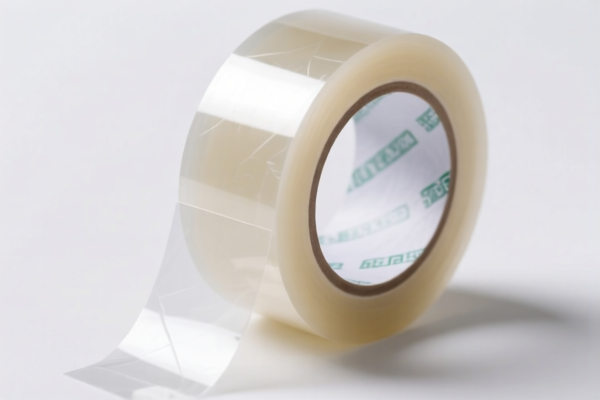

Transparent Seal

A transparent seal refers to a sealing component fabricated from a clear or translucent material, allowing visibility of the sealed contents or process. These seals are employed across diverse applications where monitoring, aesthetics, or light transmission are critical.

Materials

The selection of material dictates the seal’s performance characteristics, including temperature resistance, chemical compatibility, and optical clarity. Common materials include:

- Acrylic (PMMA): Offers excellent clarity, good weather resistance, and moderate temperature resistance. Relatively low cost.

- Polycarbonate (PC): Provides superior impact resistance and a wider temperature range than acrylic, but may be more prone to scratching.

- Glass: Exhibits exceptional clarity, chemical resistance, and temperature stability. However, it is brittle and heavier than polymers. Borosilicate glass is common for applications requiring high thermal shock resistance.

- Fluoropolymers (e.g., PTFE, FEP): Provide outstanding chemical resistance and a wide temperature range, but generally have lower clarity than acrylic or glass.

- Silicone: Offers good flexibility, temperature resistance, and biocompatibility. Clarity varies depending on formulation.

Purpose

The primary purpose of a transparent seal is to create a hermetic or fluid-tight barrier while allowing visual inspection of the enclosed space. This is crucial in applications where:

- Leak Detection: Visual inspection for leaks or contamination is required.

- Process Monitoring: Observing the sealed process (e.g., chemical reactions, fluid flow) without breaking the seal.

- Aesthetic Considerations: Maintaining visibility of the contained product or components for display or branding purposes.

- Light Transmission: Allowing light to pass through the seal for illumination or optical applications.

Function

Transparent seals function by creating a physical barrier between two surfaces, preventing the passage of fluids, gases, or contaminants. They rely on several mechanisms:

- Compression: The seal is compressed between the mating surfaces, creating a tight interface.

- Bonding: Adhesives or welding techniques can be used to create a permanent bond between the seal and the surfaces.

- Interference Fit: The seal is designed with dimensions that create a tight fit when inserted into a housing.

Usage Scenarios

- Laboratory Equipment: Sealing reaction vessels, cuvettes, and sample chambers for visual monitoring of experiments.

- Medical Devices: Enclosing sensors, fluid reservoirs, and drug delivery systems.

- Lighting Fixtures: Providing a waterproof seal for LED enclosures and light modules.

- Food and Beverage Packaging: Transparent lids and containers for visual inspection of product quality.

- Automotive Industry: Sealing headlights, taillights, and sensors.

- Electronics: Encapsulating electronic components for protection and visibility.

- Optical Systems: Sealing lenses, prisms, and filters in optical instruments.

Common Types

- O-Rings: Circular seals commonly used in static applications. Available in various materials and sizes.

- Gaskets: Flat seals cut to specific shapes and sizes. Often used in applications with irregular surfaces.

- Face Seals: Seals that create a tight interface between two flat surfaces.

- Bonded Seals: Seals permanently bonded to the mating surfaces using adhesives.

- Welded Seals: Seals created by welding the seal material to the mating surfaces.

- Custom Molded Seals: Seals designed and manufactured to specific application requirements.

Transparent seals can fall under several HS code classifications depending on the material and specific application. Here's a breakdown of relevant codes based on the provided information:

-

3923500000: This code covers articles for the conveyance or packing of goods, of plastics; stoppers, lids, caps and other closures. Specifically, it includes stoppers, lids, caps and other closures. If the transparent seal functions as a closure for packaging, this HS code is applicable. The tax rate details are: Basic tariff: 5.3%, Additional tariff: 25.0%, Post-April 2, 2025, additional tariff: 30.0%, with a total tariff of 60.3%.

-

3919102030: This code is for self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls; in rolls of a width not exceeding 20 cm; other transparent tape, not exceeding 55 m in length; not exceeding 5 cm in width. If the transparent seal is in tape form, self-adhesive, and meets the width and length specifications, this code applies. The tax rate details are: Basic tariff: 5.8%, Additional tariff: 25.0%, Post-April 2, 2025, additional tariff: 30.0%, with a total tariff of 60.8%.

-

3919905040: This code covers self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls; other; other transparent tape. If the transparent seal is in tape form, self-adhesive, and does not meet the width and length specifications of 3919102030, this code applies. The tax rate details are: Basic tariff: 5.8%, Additional tariff: 25.0%, Post-April 2, 2025, additional tariff: 30.0%, with a total tariff of 60.8%.

-

8309900090: This code covers stoppers, caps and lids (including crown corks, screw caps and pouring stoppers), capsules for bottles, threaded bungs, bung covers, seals and other packing accessories, and parts thereof, of base metal; other. If the transparent seal is made of base metal and functions as a packing accessory, this code is applicable. The tax rate details are: Basic tariff: 2.6%, Additional tariff: 25.0%, Post-April 2, 2025, additional tariff: 30.0%, with a total tariff of 57.6%.

It is important to determine the material composition and function of the transparent seal to select the correct HS code.

Customer Reviews

No reviews yet.