| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8406907500 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8406904580 | Doc | 60.0% | CN | US | 2025-05-12 |

| 8411999085 | Doc | 57.4% | CN | US | 2025-05-12 |

| 8411999030 | Doc | 57.4% | CN | US | 2025-05-12 |

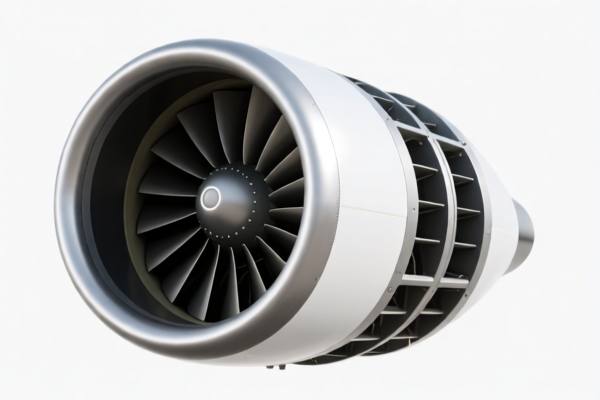

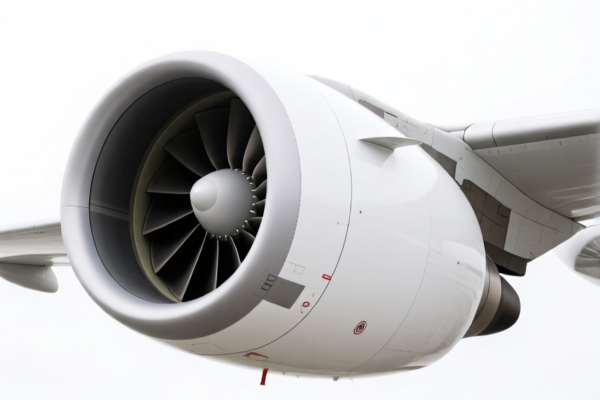

Turbine Air Outlet

A turbine air outlet is a component integral to the efficient and safe operation of turbines, primarily gas turbines and steam turbines. It manages the exhaust gases discharged from the turbine, directing them for various purposes.

Material:

The materials used in turbine air outlet construction depend heavily on the operating temperature and composition of the exhaust gases. Common materials include:

- High-Temperature Alloys: Nickel-based superalloys (e.g., Inconel, Hastelloy) are frequently used in the hottest sections due to their resistance to oxidation, corrosion, and creep at elevated temperatures.

- Stainless Steel: Various grades of stainless steel (e.g., 304, 316) are used in less thermally stressed areas.

- Carbon Steel: Lower-temperature sections may utilize carbon steel, often with protective coatings.

- Composite Materials: In some advanced applications, ceramic matrix composites (CMCs) are employed for weight reduction and improved thermal performance.

Purpose:

The primary purposes of a turbine air outlet are:

- Exhaust Gas Management: Safely and efficiently discharge exhaust gases away from the turbine.

- Energy Recovery: Capture residual energy from the exhaust gases, often through heat recovery systems.

- Noise Reduction: Minimize noise pollution generated by the high-velocity exhaust flow.

- Prevention of Backpressure: Avoid excessive backpressure on the turbine, which can reduce efficiency and damage the machine.

- Protection of Downstream Components: Prevent damage to components located downstream from the exhaust outlet.

Function:

The air outlet functions through a combination of aerodynamic design and material properties:

- Diffuser Section: Gradually expands the exhaust flow, reducing velocity and increasing static pressure. This improves energy recovery and reduces noise.

- Turning Vanes: Guide the exhaust flow in the desired direction, minimizing flow separation and turbulence.

- Silencers/Mufflers: Reduce noise levels through absorption or reflection of sound waves.

- Expansion Joints: Accommodate thermal expansion and contraction of the exhaust system.

- Flanges and Connections: Provide secure connections to the turbine and downstream components.

Usage Scenarios:

Turbine air outlets are used in a wide range of applications:

- Power Generation: Gas turbine power plants, combined cycle power plants, and steam turbine power plants.

- Aerospace: Jet engines and auxiliary power units (APUs).

- Industrial Processes: Mechanical drives for compressors, pumps, and generators in oil and gas, petrochemical, and manufacturing industries.

- Marine Applications: Gas turbines for ship propulsion and power generation.

- Waste Heat Recovery: Systems utilizing exhaust gases to generate steam or electricity.

Common Types:

- Simple Diffuser Outlets: Basic designs used in lower-temperature applications.

- Multi-Stage Diffuser Outlets: Provide more efficient energy recovery and reduced backpressure.

- Silenced Outlets: Incorporate silencers to reduce noise levels. These can be absorptive (using sound-absorbing materials) or reactive (using chambers and baffles).

- Variable Geometry Outlets: Adjust the outlet area to optimize performance under varying operating conditions.

- Ductwork Systems: Complex networks of ducts and elbows used to route exhaust gases to remote locations for heat recovery or emission control.

- SCR (Selective Catalytic Reduction) Systems Integration: Outlets designed to facilitate the integration of SCR systems for NOx reduction.

- Dry Low NOx (DLN) Outlets: Designed to minimize NOx formation and emissions.

Based on the provided information, the following HS codes may be relevant to “turbine air outlet”:

-

8406907500: This HS code covers parts of steam turbines and other vapor turbines. Specifically, it falls under Chapter 84 (Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof), Heading 8406 (Steam turbines and other vapor turbines), and Subheading 8406.90 (Parts). The further breakdown '7500' denotes 'Other' within this category. The applicable tax rate is a base tariff of 0.0%, an additional tariff of 25.0%, and a 30% additional tariff after April 2, 2025, resulting in a total tariff of 55.0%.

-

8406904580: This HS code also covers parts of steam turbines and other vapor turbines, falling under the same Chapter 84 and Heading 8406 as above. The Subheading 8406.90.45 specifies 'Of steam turbines: Other Other'. The applicable tax rate is a base tariff of 5.0%, an additional tariff of 25.0%, and a 30% additional tariff after April 2, 2025, resulting in a total tariff of 60.0%.

-

8411999085: This HS code covers parts of turbojets, turbopropellers, and other gas turbines. It falls under Chapter 84 (Nuclear reactors, boilers, machinery and mechanical appliances; parts thereof), Heading 8411 (Turbojets, turbopropellers and other gas turbines), and Subheading 8411.99 (Parts). The further breakdown '9085' denotes 'Other: Other Parts of nonaircraft gas turbines: Other: Other'. The applicable tax rate is a base tariff of 2.4%, an additional tariff of 25.0%, and a 30% additional tariff after April 2, 2025, resulting in a total tariff of 57.4%.

-

8411999030: This HS code also covers parts of turbojets, turbopropellers, and other gas turbines, falling under the same Chapter 84 and Heading 8411 as above. The Subheading 8411.99.90 specifies 'Other: Other Parts of nonaircraft gas turbines: Rotors or spindles and rotor or spindle assemblies'. The applicable tax rate is a base tariff of 2.4%, an additional tariff of 25.0%, and a 30% additional tariff after April 2, 2025, resulting in a total tariff of 57.4%.

According to the provided reference material, the HS code options related to 'turbine air outlet' are limited, with only the following 4 found.

Customer Reviews

No reviews yet.