| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 7308903000 | Doc | 80.0% | CN | US | 2025-05-12 |

| 7308906000 | Doc | 80.0% | CN | US | 2025-05-12 |

| 9406900130 | Doc | 82.9% | CN | US | 2025-05-12 |

| 9406900190 | Doc | 82.9% | CN | US | 2025-05-12 |

| 7326908630 | Doc | 82.9% | CN | US | 2025-05-12 |

| 8307103000 | Doc | 58.8% | CN | US | 2025-05-12 |

| 8307106000 | Doc | 58.8% | CN | US | 2025-05-12 |

| 8306100000 | Doc | 35.8% | CN | US | 2025-05-12 |

| 8306100000 | Doc | 35.8% | CN | US | 2025-05-12 |

| 8304000000 | Doc | 33.9% | CN | US | 2025-05-12 |

| 9403200075 | Doc | 80.0% | CN | US | 2025-05-12 |

| 9403999020 | Doc | 80.0% | CN | US | 2025-05-12 |

| 7610900080 | Doc | 85.7% | CN | US | 2025-05-12 |

| 7610900060 | Doc | 85.7% | CN | US | 2025-05-12 |

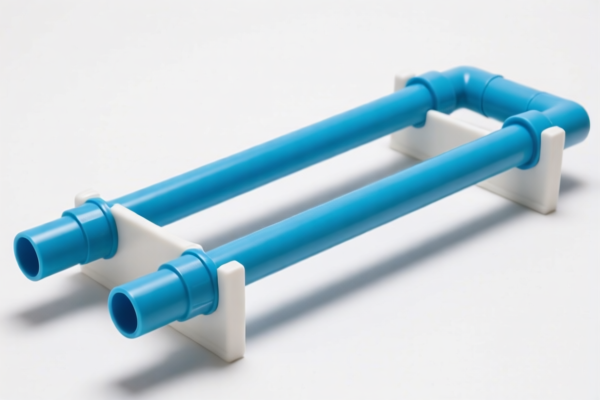

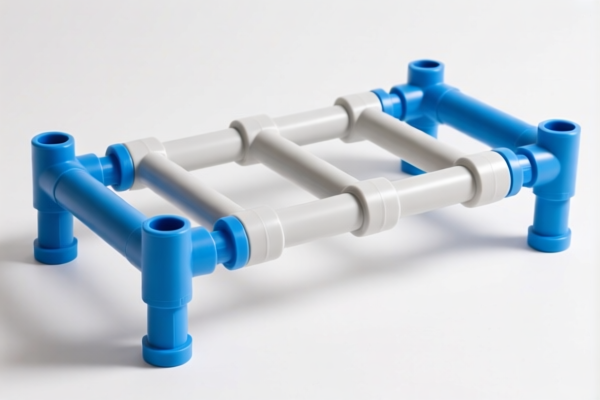

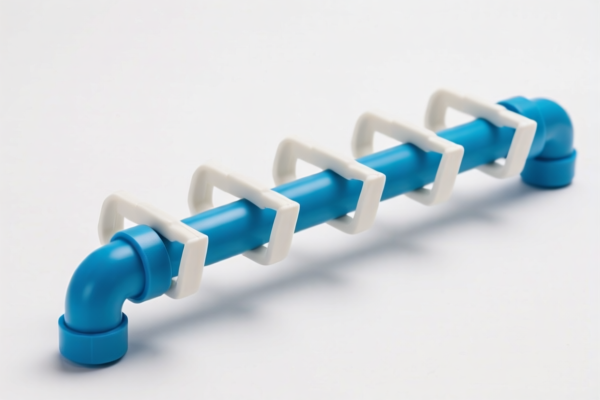

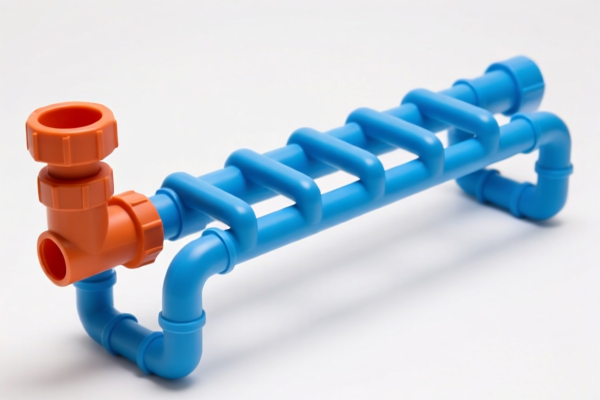

Water Pipe Rack

A water pipe rack, also known as a pipe support system, is a structural framework designed to support and secure water piping in various applications. These racks are crucial for the safe and efficient distribution of water, preventing stress, vibration, and potential damage to the piping network.

Material:

- Steel: The most common material due to its high strength, durability, and cost-effectiveness. Carbon steel is frequently used, often with protective coatings like galvanization, epoxy, or paint to resist corrosion. Stainless steel is employed in applications requiring higher corrosion resistance, such as potable water systems or harsh environments.

- Aluminum: Lighter than steel, making it suitable for applications where weight is a concern. Offers good corrosion resistance but generally lower strength than steel.

- Plastic (PVC, CPVC, Polypropylene): Used for smaller diameter pipes, low-pressure systems, and corrosive environments where metal corrosion is a significant issue. Lower load-bearing capacity compared to metal options.

- Fiberglass Reinforced Polymer (FRP): Offers excellent corrosion resistance and non-conductivity, making it suitable for specialized applications.

Purpose:

- Support: Provides physical support to prevent pipes from sagging, bending, or collapsing under their own weight and the weight of the contained fluid.

- Isolation: Isolates pipes from structural elements to reduce noise and vibration transmission.

- Protection: Protects pipes from external damage, such as impact or abrasion.

- Expansion/Contraction Accommodation: Allows for thermal expansion and contraction of pipes without causing stress on the piping system or supporting structure.

- Accessibility: Facilitates access for maintenance, inspection, and repairs.

Function:

Water pipe racks function by distributing the load of the piping system to the supporting structure (building steel, concrete foundations, etc.). They utilize a combination of components to achieve this:

- Main Supports: Vertical columns or beams that transfer the load to the foundation.

- Horizontal Supports: Beams or rails that support the pipes directly.

- Pipe Clamps/Supports: Secure the pipes to the horizontal supports, allowing for movement due to thermal expansion. Types include:

- Shoe Supports: Support pipes from below.

- U-Bolts: Clamp around pipes.

- Hangers: Support pipes from above.

- Risers Clamps: Support vertical pipes.

- Anchors: Restrict pipe movement at specific points.

- Guides: Allow controlled pipe movement in a specific direction.

- Bracing: Provides lateral stability to the piping system, especially important in seismic zones.

Usage Scenarios:

- Industrial Plants: Chemical processing, power generation, oil and gas refineries.

- Commercial Buildings: HVAC systems, plumbing, fire suppression systems.

- Water Treatment Facilities: Distribution of treated water.

- Wastewater Treatment Plants: Collection and conveyance of wastewater.

- Plumbing Systems: Support for water lines within buildings.

- Fire Protection Systems: Support for sprinkler piping.

Common Types:

- Standard Pipe Racks: Pre-engineered systems with standardized components for common applications.

- Custom Pipe Racks: Designed and fabricated to meet specific project requirements, often used in complex or unusual piping configurations.

- Seismic Pipe Racks: Designed to withstand earthquake forces, incorporating bracing and specialized connections.

- Modular Pipe Racks: Pre-assembled sections that can be easily connected to create a complete pipe support system.

- Unistrut Systems: Utilizing Unistrut channels and fittings for versatile and adaptable pipe support.

Based on the provided information, “water pipe rack” can be classified under the following HS codes:

- 7326908630: Other articles of iron or steel; Other; Other; Other: Hangers and similar supports for tubes and pipes. This code covers supports specifically designed for tubes and pipes, which aligns with the function of a water pipe rack.

- 9403200075: Other furniture and parts thereof; Other metal furniture; Other: Counters, lockers, racks, display cases, shelves, partitions and similar fixtures: Boltless or press-fit steel shelving units prepackaged for sale as described in statistical note 3 to this chapter. If the water pipe rack is constructed as a shelving unit, particularly a boltless or press-fit steel unit prepackaged for sale, this code may be applicable.

- 9403999020: Other furniture and parts thereof; Parts; Other; Other: Of metal: Welded wire rack, whether or not galvanized, plated or coated. If the rack is made of welded wire and is a part of furniture, this code could be considered.

Regarding HS code 7326908630, it specifically refers to hangers and supports for tubes and pipes made of iron or steel.

Regarding HS code 9403200075, please note that this code applies to boltless or press-fit steel shelving units prepackaged for sale.

Regarding HS code 9403999020, the rack must be made of welded wire and be considered a part of furniture.

Customer Reviews

No reviews yet.