| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8515310000 | Doc | 56.6% | CN | US | 2025-05-12 |

| 8479899599 | Doc | 82.5% | CN | US | 2025-05-12 |

| 8468801000 | Doc | 57.9% | CN | US | 2025-05-12 |

| 8515390040 | Doc | 56.6% | CN | US | 2025-05-12 |

| 8468805000 | Doc | 55.0% | CN | US | 2025-05-12 |

Welding Machine

A welding machine is a power supply that produces a high-current electrical arc, used to melt and fuse materials, typically metals, together. The process creates a strong bond through coalescence, often with the addition of filler material.

Materials Welded

While steel and stainless steel are the most common materials welded, machines and techniques exist for joining a wide range of metals including:

- Aluminum: Requires specialized techniques (AC TIG welding is common) due to its oxide layer and thermal conductivity.

- Cast Iron: Often requires specific electrodes and pre- and post-heating procedures.

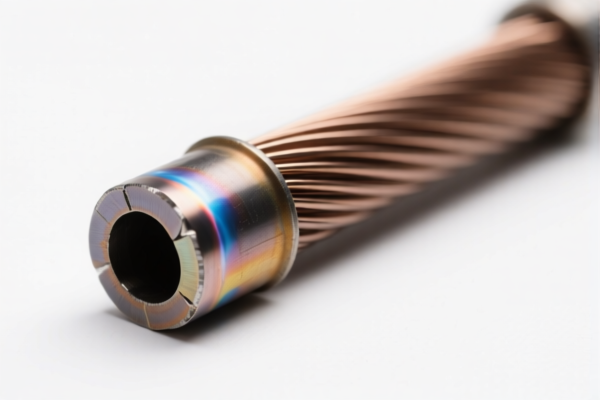

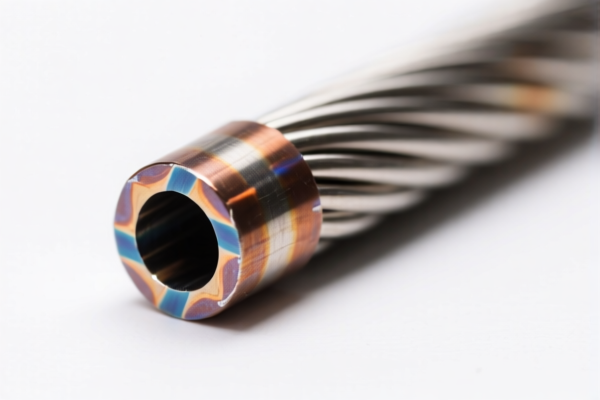

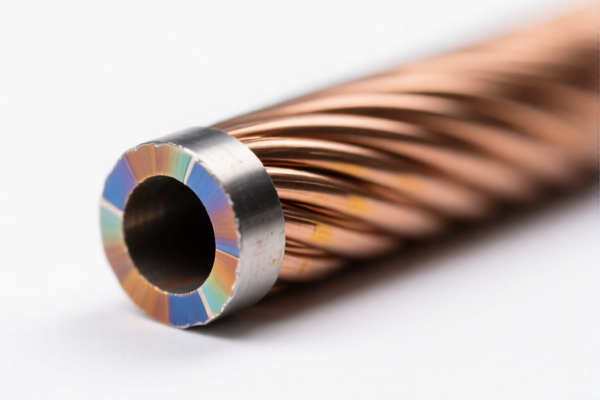

- Copper & Brass: Can be challenging due to their high thermal conductivity and oxidation potential.

- Titanium: Requires shielding from atmospheric contamination, typically using inert gases.

- Nickel Alloys: Used in specialized applications requiring corrosion resistance.

Purpose

The primary purpose of a welding machine is to permanently join metal parts, creating structures, repairing damage, or fabricating components. Welding is crucial in industries such as:

- Construction: Building bridges, skyscrapers, and infrastructure.

- Manufacturing: Automotive, aerospace, shipbuilding, and general fabrication.

- Repair & Maintenance: Fixing broken machinery, pipelines, and equipment.

- Art & Sculpture: Creating artistic metalwork.

Function

Welding machines function by:

- Power Supply: Providing a consistent and high-current electrical source.

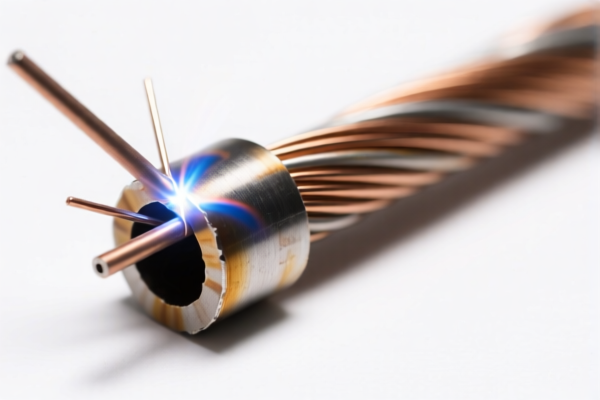

- Arc Generation: Creating an electrical arc between an electrode and the workpiece. The arc generates intense heat.

- Melting & Fusion: The heat melts the base materials at the joint, and often a filler metal is added to create a stronger weld.

- Shielding: Protecting the weld pool from atmospheric contamination (oxygen, nitrogen, hydrogen) which can weaken the weld. This is achieved through shielding gases, flux coatings on electrodes, or specialized welding environments.

- Cooling & Solidification: Allowing the weld pool to cool and solidify, forming a permanent bond.

Usage Scenarios

Welding machines are employed in diverse settings:

- Shop Fabrication: Controlled environments for precise welding of components.

- Field Welding: On-site welding for construction, repair, and pipeline work.

- Automated Welding: Using robotic systems for high-volume production.

- DIY/Home Use: Smaller machines for light repairs and hobby projects.

Common Types

- SMAW (Shielded Metal Arc Welding) / Stick Welding: Uses a coated electrode to provide both the arc and shielding. Versatile, portable, and relatively inexpensive.

- GMAW (Gas Metal Arc Welding) / MIG Welding: Uses a continuous wire electrode and a shielding gas. Faster and easier to learn than stick welding, suitable for thinner materials.

- GTAW (Gas Tungsten Arc Welding) / TIG Welding: Uses a non-consumable tungsten electrode and a shielding gas. Provides high-quality, precise welds, often used for aluminum and stainless steel.

- FCAW (Flux-Cored Arc Welding): Uses a tubular electrode containing flux. Suitable for outdoor welding and thicker materials.

- SAW (Submerged Arc Welding): Uses a granular flux covering the weld area. Automated process for thick materials, high deposition rates.

- Resistance Welding: Uses pressure and electrical current to join materials. Common in automotive manufacturing (spot welding).

- Laser Beam Welding: Uses a focused laser beam to melt and fuse materials. Precise, high-quality welds, but expensive.

- Plasma Arc Welding: Uses a constricted arc to melt and fuse materials. Versatile, precise, and can weld a variety of metals.

Welding machines encompass a variety of equipment used to join metals through the application of heat, pressure, or both. The specific type of welding machine dictates its classification and associated tariff rates.

The following HS codes are relevant to welding machines, based on the provided information:

- 8468801000: This code covers machinery and apparatus for soldering, brazing or welding, whether or not capable of cutting, other than those of heading 8515; gas-operated surface tempering machines and appliances; parts thereof: Other machinery and apparatus: Hand-directed or -controlled. This includes hand-held or manually operated welding equipment.

- 8515310000: This code refers to Electric (including electrically heated gas), laser or other light or photon beam, ultrasonic, electron beam, magnetic pulse or plasma arc soldering, brazing or welding machines and apparatus, whether or not capable of cutting; electric machines and apparatus for hot spraying of metals or cermets; parts thereof: Machines and apparatus for arc (including plasma arc) welding of metals: Fully or partly automatic. This covers automatic or semi-automatic arc welding machines.

- 8515390020: This code covers Electric (including electrically heated gas), laser or other light or photon beam, ultrasonic, electron beam, magnetic pulse or plasma arc soldering, brazing or welding machines and apparatus, whether or not capable of cutting; electric machines and apparatus for hot spraying of metals or cermets; parts thereof: Machines and apparatus for arc (including plasma arc) welding of metals: Other Non-rotating type: AC transformer type. This specifically applies to non-rotating, AC transformer-based arc welding machines.

Explanation of HS Code Structure (based on provided information):

- Chapter 84: Covers machinery and mechanical appliances.

- Chapter 85: Covers electrical machinery and equipment.

- Heading 68: Within Chapter 84, this heading specifically addresses machinery for soldering, brazing, or welding.

- Heading 15: Within Chapter 85, this heading covers electric soldering, brazing, or welding machines.

- Subheading 31: Within Heading 15, this subheading focuses on arc welding machines that are fully or partly automatic.

- Subheading 39: Within Heading 15, this subheading covers other arc welding machines, specifically non-rotating type AC transformer type.

Tariff Information (based on provided information):

All listed HS codes are subject to a base tariff rate, a surcharge, and a potential tariff change in 2025.

- 8468801000: Base tariff: 2.9%, Surcharge: 25.0%, Post-2025.4.2 Surcharge: 30.0%, Total tariff: 57.9%.

- 8515310000 & 8515390020: Base tariff: 1.6%, Surcharge: 25.0%, Post-2025.4.2 Surcharge: 30.0%, Total tariff: 56.6%.

Customer Reviews

No reviews yet.