| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 6801000000 | Doc | 57.8% | CN | US | 2025-05-12 |

| 6804300000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8460310040 | Doc | 59.4% | CN | US | 2025-05-12 |

| 8460390020 | Doc | 59.4% | CN | US | 2025-05-12 |

| 3801900000 | Doc | 59.9% | CN | US | 2025-05-12 |

| 3801101000 | Doc | 58.7% | CN | US | 2025-05-12 |

| 3816001000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 3816002050 | Doc | 58.0% | CN | US | 2025-05-12 |

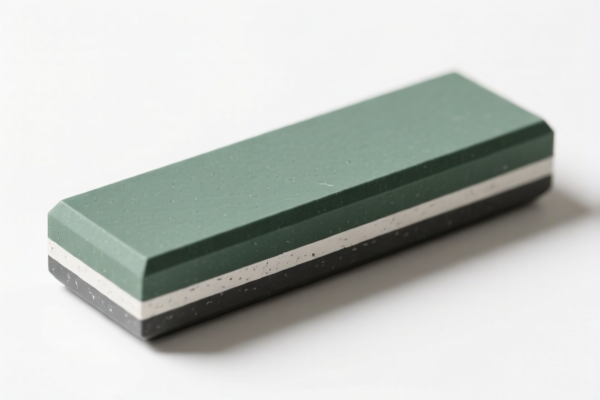

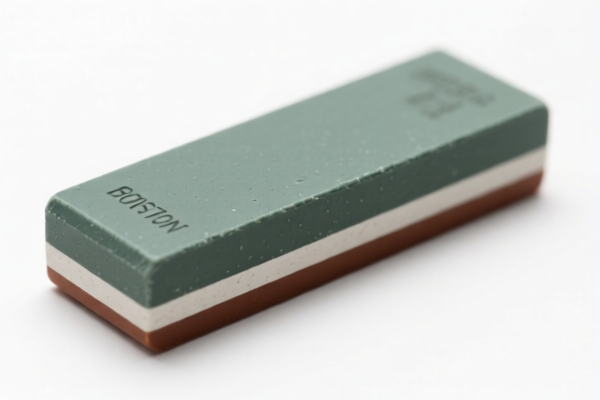

Whetstone

A whetstone is a stone used for sharpening the edge of a blade, typically a knife, axe, or other cutting tool. The process involves abrading the blade against the stone to remove material and create a new, sharper edge.

Material:

Whetstones are composed of various abrasive materials, broadly categorized as:

- Natural Stones: Historically, whetstones were sourced from natural geological formations. These include:

- Arkansas Stone: Composed of novaculite, known for its hardness and fine grit, producing a very sharp, polished edge. Variations include soft, medium, and hard stones, differing in abrasive particle size.

- Welsh Slate: A softer stone often used for coarser sharpening.

- Serpentine: Another natural stone with varying grit levels.

- Synthetic Stones: Manufactured using abrasive materials bonded together. These offer consistency and a wider range of grit options. Common synthetic abrasives include:

- Aluminum Oxide: A hard, durable abrasive suitable for many blade types.

- Silicon Carbide: A more aggressive abrasive, effective for faster material removal.

- Ceramic: Very hard and long-lasting, often used for fine polishing and maintaining edges.

Purpose:

The primary purpose of a whetstone is to restore or enhance the sharpness of a blade edge. Sharpness is achieved by:

- Removing dull or damaged metal.

- Creating a consistent bevel (angle) on the blade.

- Polishing the edge for optimal cutting performance.

Function:

Whetstones function through abrasion. The abrasive particles on the stone’s surface remove microscopic layers of metal from the blade as it is drawn across the stone. The process typically involves:

- Flattening: Ensuring the stone surface is level for even sharpening.

- Coarse Sharpening: Removing significant metal to repair damage or reshape the blade. Utilizes lower grit stones.

- Medium Sharpening: Refining the edge and removing scratches from coarse sharpening.

- Fine Sharpening: Polishing the edge for maximum sharpness and smoothness. Uses higher grit stones.

- Stropping: Aligning the microscopic teeth of the blade edge for an even sharper and more durable edge (often done with leather or other materials after whetstone use).

Usage Scenarios:

- Kitchen Knives: Maintaining the sharpness of chef’s knives, paring knives, and other kitchen tools.

- Woodworking Tools: Sharpening chisels, plane blades, and other tools used in woodworking.

- Outdoor Tools: Sharpening axes, hatchets, and other tools used for camping, hunting, or forestry.

- Straight Razors: Essential for maintaining the extremely sharp edge of straight razors.

- Professional Applications: Used by chefs, carpenters, barbers, and other professionals who require extremely sharp tools.

Common Types:

- Water Stones: Require water lubrication during use. Water helps to carry away metal particles and keeps the stone clean. Generally softer and wear faster than oil stones.

- Oil Stones: Require oil lubrication during use. Oil prevents clogging and provides a smoother cutting action. Typically harder and more durable than water stones.

- Diamond Stones: Utilize diamond particles as the abrasive. Very aggressive and effective for sharpening hard steels. Can be used with water or oil.

- Combination Stones: Feature different grit levels on opposite sides, allowing for both coarse and fine sharpening.

- Lapping Plates: Flat plates used to flatten whetstones and maintain their level surface.

Whetstones are utilized for sharpening, polishing, or finishing metal tools and surfaces. They fall under several classifications depending on their composition and application.

Here are the relevant HS codes based on the provided reference material:

-

6804300000: This HS code covers millstones, grindstones, grinding wheels, and similar items without frameworks, used for grinding, sharpening, polishing, or trueing. Specifically, it includes hand sharpening or polishing stones.

- 68: Chapter 68 represents articles of stone, plaster, lime, cement, asbestos, mica or similar materials.

- 04: Heading 04 denotes millstones, grindstones, grinding wheels, and the like.

- 300000: This subheading specifically refers to hand sharpening or polishing stones.

-

3801101000: This HS code covers artificial graphite plates, rods, powder, and other forms, wholly or partly manufactured, for manufacturing into brushes for electric generators, motors, or other machines or appliances. While not directly a whetstone, graphite can be a component in some whetstone formulations.

- 38: Chapter 38 represents chemical products.

- 01: Heading 01 denotes artificial graphite.

- 101000: This subheading specifically refers to plates, rods, powder, and other forms for manufacturing brushes.

-

3801900000: This HS code covers other artificial graphite preparations based on graphite or other carbon in the form of pastes, blocks, plates, or other semimanufactures. This could include some whetstone compositions.

- 38: Chapter 38 represents chemical products.

- 01: Heading 01 denotes artificial graphite.

- 900000: This subheading covers other forms of artificial graphite.

Regarding HS code 6804300000, it is important to note that this specifically covers stones without frameworks. If the whetstone has a framework or is part of a larger machine, a different HS code may be applicable.

Customer Reviews

No reviews yet.