| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 3919102030 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3919102040 | Doc | 60.8% | CN | US | 2025-05-12 |

| 3921904010 | Doc | 34.2% | CN | US | 2025-05-12 |

| 3921904090 | Doc | 34.2% | CN | US | 2025-05-12 |

| 5603110010 | Doc | 55.0% | CN | US | 2025-05-12 |

| 5602903000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 5602906000 | Doc | 61.3% | CN | US | 2025-05-12 |

| 7006004010 | Doc | 59.9% | CN | US | 2025-05-12 |

| 7006004050 | Doc | 59.9% | CN | US | 2025-05-12 |

| 7003120000 | Doc | 56.4% | CN | US | 2025-05-12 |

| 7003190000 | Doc | 56.3% | CN | US | 2025-05-12 |

| 7020006000 | Doc | 60.0% | CN | US | 2025-05-12 |

| 7020003000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 9610000000 | Doc | 33.5% | CN | US | 2025-05-12 |

Window Film

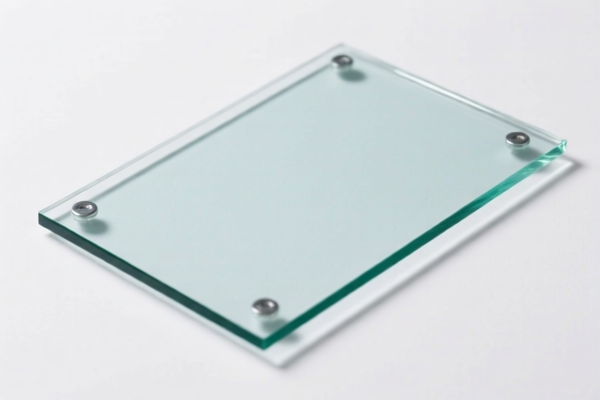

Window film is a thin, laminate material applied to glass surfaces to alter the glass’s properties. It serves a variety of purposes, ranging from enhancing privacy and security to improving energy efficiency and aesthetics.

Materials

Window films are typically constructed from one or more layers of polyester, though the specific composition varies depending on the intended function. Common materials include:

- Polyester (PET): The base layer providing structural integrity.

- Adhesive: A crucial component for bonding to glass; types include pressure-sensitive, static cling, and wet application adhesives.

- Metal Layers: Often incorporated for heat rejection, glare reduction, and UV blocking. These can be aluminum, silver, or other reflective metals.

- Dye Layers: Used for tinting and controlling visible light transmission.

- Ceramic Particles: Provide superior heat rejection and clarity compared to dyed films.

- Security Layers: Thicker, more robust layers designed to resist shattering.

Purpose and Function

The primary functions of window film include:

- Heat Rejection: Reduces solar heat gain, lowering cooling costs and improving comfort.

- Glare Reduction: Minimizes harsh sunlight, enhancing visibility and reducing eye strain.

- UV Protection: Blocks harmful ultraviolet rays, preventing fading of interior furnishings and protecting skin.

- Privacy: Obscures the view from outside, providing increased security and seclusion.

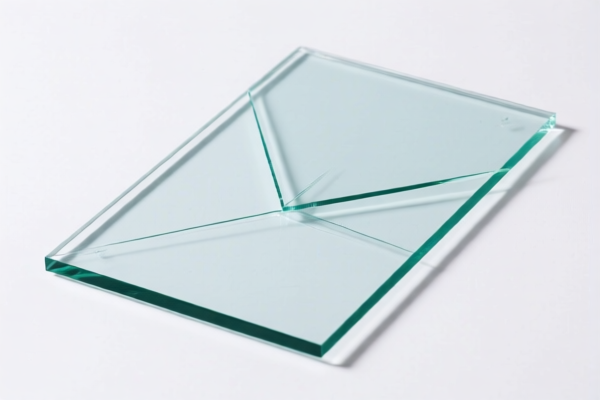

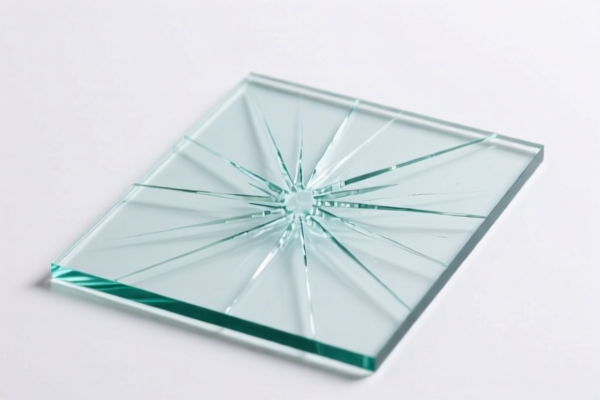

- Security: Strengthens glass, making it more resistant to breakage from impacts or forced entry.

- Safety: Holds broken glass fragments together, reducing the risk of injury.

- Decorative Appearance: Adds color, texture, or patterns to glass surfaces for aesthetic purposes.

Usage Scenarios

Window film is used in a wide range of applications:

- Residential: Homes to improve energy efficiency, privacy, and comfort.

- Commercial: Offices, retail stores, and restaurants to reduce energy costs, enhance security, and improve aesthetics.

- Automotive: Cars to reduce heat, glare, and UV exposure, and to enhance privacy.

- Government/Public Buildings: To improve security, energy efficiency, and safety.

- Marine: Boats and yachts to reduce heat and glare, and to protect interiors.

Common Types

- Dyed Film: The most affordable option, offering basic heat rejection and glare reduction. Generally lower clarity and durability.

- Metalized Film: Contains metal layers for improved heat rejection and glare reduction. Can sometimes interfere with radio signals.

- Ceramic Film: Offers superior heat rejection, clarity, and durability compared to dyed or metalized films. More expensive.

- Carbon Film: Provides good heat rejection and UV protection, with a matte finish that reduces glare.

- Security Film: Thick, multi-layered films designed to resist shattering and forced entry.

- Privacy Film: Obscures the view through the glass, available in various levels of opacity. Includes frosted, mirrored, and one-way mirror options.

- Decorative Film: Available in a wide range of colors, patterns, and textures for aesthetic purposes.

- Anti-Graffiti Film: Protects glass surfaces from vandalism and graffiti.

- Sputtered Film: Offers excellent durability and color stability, often used in architectural applications.

Window film can refer to various plastic films applied to glass surfaces for different purposes, such as privacy, heat reduction, or safety. Based on the provided reference material, the following HS codes may be relevant:

-

7006004010: Glass of heading 7003, 7004 or 7005, bent, edge-worked, engraved, drilled, enameled or otherwise worked, but not framed or fitted with other materials: Other: Other Having an absorbent or reflecting layer. This code applies to worked glass, and if the window film has a reflective layer for heat reduction, it could fall under this classification.

- 70: Glass and glass products.

- 06: Glass of heading 7003, 7004 or 7005, bent, edge-worked, engraved, drilled, enameled or otherwise worked, but not framed or fitted with other materials.

- 004010: Specifically for glass with an absorbent or reflecting layer.

-

7006004050: Glass of heading 7003, 7004 or 7005, bent, edge-worked, engraved, drilled, enameled or otherwise worked, but not framed or fitted with other materials: Other: Other. This is a broader category for worked glass that doesn't specifically have an absorbent or reflecting layer. If the window film is applied to glass and the glass is worked (bent, edge-worked, etc.), this code might be applicable.

- 70: Glass and glass products.

- 06: Glass of heading 7003, 7004 or 7005, bent, edge-worked, engraved, drilled, enameled or otherwise worked, but not framed or fitted with other materials.

- 004050: For other worked glass.

-

7003120000: Cast glass and rolled glass, in sheets or profiles, whether or not having an absorbent, reflecting or non-reflecting layer, but not otherwise worked: Nonwired sheets: Colored throughout the mass (body tinted), opacified, flashed or having an absorbent, reflecting or non-reflecting layer. If the window film is a cast or rolled glass sheet with a color tint or reflective layer, this code could be considered.

- 70: Glass and glass products.

- 03: Cast glass and rolled glass.

- 120000: Specifically for nonwired sheets that are colored, opacified, flashed, or have a reflective layer.

-

7003190000: Cast glass and rolled glass, in sheets or profiles, whether or not having an absorbent, reflecting or non-reflecting layer, but not otherwise worked: Nonwired sheets: Other. This applies to nonwired cast or rolled glass sheets that don't fall into the more specific category of 7003120000.

- 70: Glass and glass products.

- 03: Cast glass and rolled glass.

- 190000: For other nonwired sheets.

-

3919102030: Self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls: In rolls of a width not exceeding 20 cm: Other Transparent tape, not exceeding 55 m in length: Not exceeding 5 cm in width. If the window film is a self-adhesive plastic film in rolls less than 20 cm wide and less than 55 m in length, this code may be applicable.

- 39: Plastics and articles thereof.

- 19: Self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics.

- 102030: Specifically for self-adhesive plastic film in rolls less than 20 cm wide and less than 55 m in length.

-

3919102040: Self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics, whether or not in rolls: In rolls of a width not exceeding 20 cm: Other Other: Transparent tape, not exceeding 55 m in length: Other. If the window film is a self-adhesive plastic film in rolls less than 20 cm wide, this code may be applicable.

- 39: Plastics and articles thereof.

- 19: Self-adhesive plates, sheets, film, foil, tape, strip and other flat shapes, of plastics.

- 102040: Specifically for self-adhesive plastic film in rolls less than 20 cm wide.

Regarding HS codes 3919102030 and 3919102040, please note the width and length restrictions (not exceeding 20 cm wide and 55 m in length). The total tax rate for these codes is 60.8%.

Customer Reviews

No reviews yet.