Found 13 matching results

(CN → US)

| HS Code | Official Doc | Tariff Rate | Origin | Destination | Effective Date |

|---|---|---|---|---|---|

| 8479899550 | Doc | 32.5% | CN | US | 2025-05-12 |

| 8479899550 | Doc | 32.5% | CN | US | 2025-05-12 |

| 8487900080 | Doc | 83.9% | CN | US | 2025-05-12 |

| 8487900040 | Doc | 58.9% | CN | US | 2025-05-12 |

| 7326200090 | Doc | 83.9% | CN | US | 2025-05-12 |

| 7326908688 | Doc | 82.9% | CN | US | 2025-05-12 |

| 7312900000 | Doc | 80.0% | CN | US | 2025-05-12 |

| 8311900000 | Doc | 55.0% | CN | US | 2025-05-12 |

| 8307103000 | Doc | 58.8% | CN | US | 2025-05-12 |

| 8307106000 | Doc | 58.8% | CN | US | 2025-05-12 |

| 3926903000 | Doc | 59.2% | CN | US | 2025-05-12 |

| 3926909989 | Doc | 42.8% | CN | US | 2025-05-12 |

| 3923400050 | Doc | 60.3% | CN | US | 2025-05-12 |

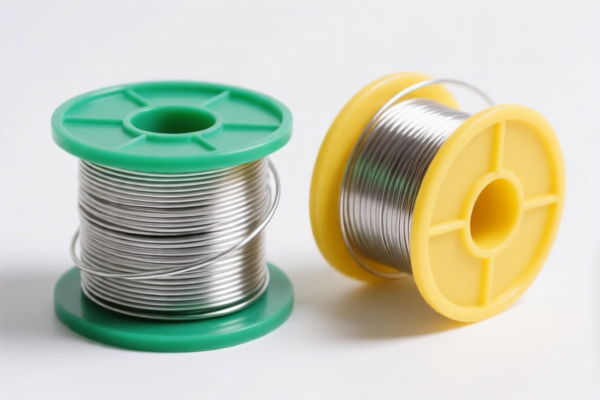

Wire Spool Holder

A wire spool holder is a device used to securely hold and dispense wire, thread, or similar materials wound onto a spool. These holders facilitate controlled unwinding and prevent tangling, kinking, or uncontrolled release of the wire during various applications.

Material:

- Metal: Steel, stainless steel, and aluminum are common for robust applications and heavier spools. Often powder-coated for corrosion resistance.

- Plastic: ABS, polypropylene, and nylon are used for lighter-duty applications, offering cost-effectiveness and resistance to certain chemicals.

- Wood: Historically used, and still found in some applications, particularly for larger spools or specific aesthetic requirements.

- Combination: Some holders utilize a mix of materials, like a metal base with plastic spool arms.

Purpose:

The primary purpose is to manage wire during processes like:

- Welding: Essential for feeding welding wire smoothly and consistently.

- 3D Printing: Holds filament spools, ensuring consistent extrusion.

- Sewing/Knitting: Supports thread spools for efficient and organized sewing or knitting.

- Electrical Work: Manages wire during installation and repair.

- Crafting/DIY: Used in various hobby and crafting applications involving wire.

Function:

- Secure Spool Mounting: Holds the spool firmly in place, preventing it from rolling or unraveling.

- Controlled Wire Feed: Allows for smooth, consistent dispensing of wire without tangles or snags.

- Rotation: Many designs allow the spool to rotate freely, facilitating easy unwinding.

- Tension Control: Some models incorporate mechanisms to adjust the tension of the wire feed.

- Portability: Various designs offer portability for use in different locations.

Usage Scenarios:

- Welding Workshops: Fixed or portable holders are used extensively for MIG, TIG, and stick welding.

- 3D Printing Stations: Placed alongside 3D printers to support filament spools.

- Sewing Rooms: Used with sewing machines or for hand sewing.

- Electrical Panels/Workbenches: Facilitates wire installation and repair.

- Construction Sites: Portable holders for on-site electrical work.

- Home Workshops/Craft Rooms: Versatile use in various DIY projects.

Common Types:

- Floor Stands: Large, heavy-duty stands for large spools, often with casters for mobility.

- Tabletop Stands: Compact stands for smaller spools, suitable for workbench use.

- Spool Guns: Integrated holders and feed mechanisms for welding wire, used with MIG welders.

- Thread Stands: Specifically designed for sewing thread spools, often with multiple arms.

- Bobbin Stands: Smaller holders for bobbins of thread.

- Adjustable Stands: Designed to accommodate various spool sizes.

- Magnetic Stands: Utilize magnets to attach to metal surfaces.

- 3D Printer Filament Holders: Often include features to reduce filament tangling and humidity.

Based on the provided information, the following HS codes may be relevant to “wire spool holder”:

- 8311900000: This HS code covers “Wire, rods, tubes, plates, electrodes and similar products of base metal or of metal carbides, coated or cored with flux material, of a kind used for soldering, brazing, welding or deposition of metal or of metal carbides; wire and rods, of agglomerated base metal powder, used for metal spraying; base metal parts thereof: Other”. This could apply if the spool holder is made of metal and is used in conjunction with welding or metal spraying processes. The base metal parts are included in this code.

- 7312900000: This HS code covers “Stranded wire, ropes, cables, plaited bands, slings and the like, of iron or steel, not electrically insulated: Other”. If the spool holder is constructed from stranded wire, ropes, or cables of iron or steel and is not electrically insulated, this code may be applicable.

- 7326200090: This HS code covers “Articles of iron or steel wire Other”. If the spool holder is made of iron or steel wire, this code could be relevant.

- 3923400050: This HS code covers “Articles for the conveyance or packing of goods, of plastics; stoppers, lids, caps and other closures, of plastics: Spools, cops, bobbins and similar supports Other”. If the spool holder is made of plastic and functions as a support for spools, this code may be applicable.

Regarding HS code 3923400050, please note that the item is classified as an article for the conveyance or packing of goods made of plastics.

Customer Reviews

No reviews yet.